Patrick,

Yahoo! We are removing rust as I type.

I didn’t have Washing Soda so I converted some Baking Soda by baking it at 325deg for 1 hour.

I took the liberty to deviate from the stainless electrolytic rust removing container and used a plain old cat litter bucket. It’s what I had handy and also I read that using stainless will leach heavy metal into the solution. It won’t harm the rust removal process but the effects of chrome and whatever else is in stainless isn’t the best for us humans.

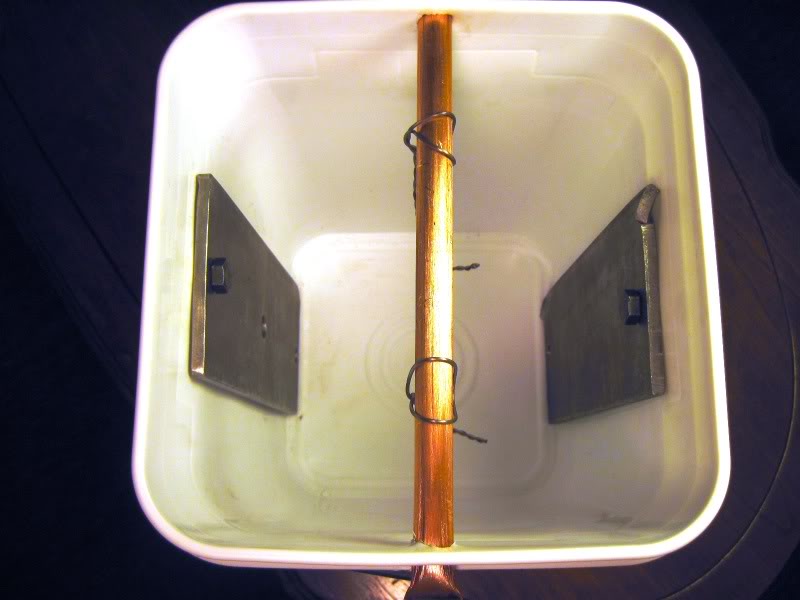

Here’s what I started with.

I bolted two sacrificial anodes (mild steel plates) into the bucket and used a piece of copper pipe to hang the cathode wires on.

I twisted the hangers out of bailing wire. It was pretty rusty from setting out in the garage so I sanded it to assure good conduction.

The two sacrificial anode plates are bonded together using a strand of house wire.

The power source that I used is one of those wall warts that clogs up just every power strip under every desk on the entire earth.

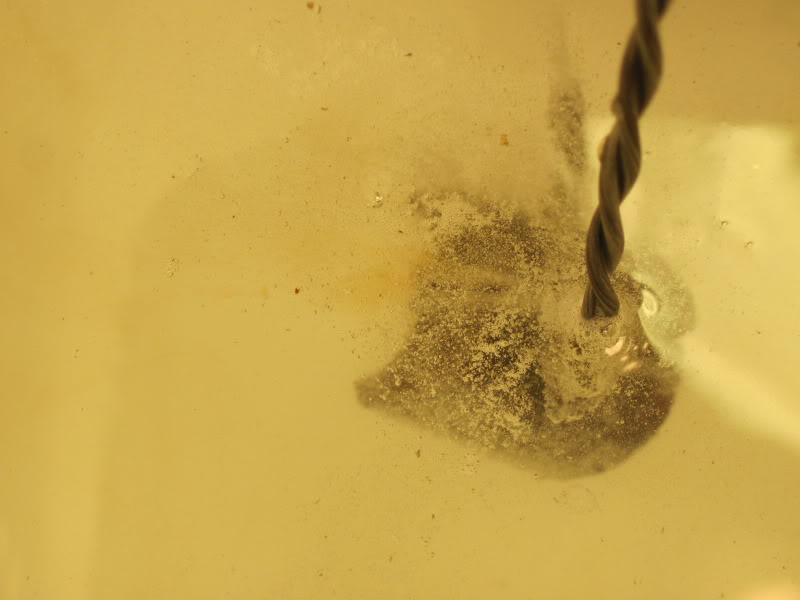

I mixed about ¼ cup of Washing Soda into 2 gals water, hung a couple rusty parts on the hangers and hit the juice. I was immediately surprised how vigorously it bubbled especially considering how small the power supply is.

This is after just a couple minutes. After about an hour the water is completely nasty with rust from the parts but mainly debree off of the sacrificial anodes. Now I can’t even see the parts but occasionally I pull one of them out and they appear to be derusting very nicely. I’ll post some results pictures tomorrow.

The barrel and receiver will require a special tank that I haven’t quite worked out yet.

Oh yah, I scrounged around in the basement and found some lead bullets that should work good for slugging the bore.

Also you had asked for more pictures of the end of the barrel. I assume you wanted to see the condition of the crown. Let me know if these pictures don’t show what you wanted to see.

As far as the .43 Spanish brass and bullets, it’s just not in the budget yet. I do have some flowers of sulfur that could be used to cast the chamber if that would be helpful?

It’ll take me a few days to get all of the small parts de-rusted but we are turning the corner and things are going to look better from now on. I have access to an ultrasonic cleaner at work so all of the small parts will get a follow up wash.

Hmm, now what to use for a barrel tank…

Joel.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

Register To Reply

Register To Reply