-

Legacy Member

I stand to be corrected, but I think that the cocking piece is NEVER meant to strike the rear of the bolt body.

The collar on the striker is absolutely intended to strike the rear of the bolt head. This does two things: 1. Ensures constant striker protrusion, and, 2. Drastically reduces the potential for damage to the thread / mating surfaces at the tail-end of the striker.

The first point is tied in with the selective fitting of the striker to the bolt head. This was, I understand, done as part of selecting a set of components to assemble a bolt. The idea is that gauged components were selected for "best fit'.

The bolt lugs had to have the correct amount of engagement with the shoulders in the receiver.

The bolt head had to fit so that the "wing" of the head lined up with the lug on the bolt body or no more than a few degrees over.

The striker had to fit the bolt head within the specified protrusion range.

The striker had to tighten into the cocking piece such that:

a. The protrusion previously set was maintained,

b. The keeper screw would enter the rear of the cocking piece and prevent rotation, and,

c. The safety notches in the cocking piece would be correctly aligned with the driving surface of the locking bolt when cocked or at rest.

Remember that early SMLEs used a striker that had a lug which lined up with a notch in the rear of the bolt head. This was to ensure that if the bolt was not closed fully, the striker could not ignite a cartridge and do some serious damage. This required some seriously fine machining to ensure that the lug was correctly aligned with the keeper screw recess at the rear and, just because they could, the qualifying of the thread at the rear of the striker. This striker required a LOT of careful setup and gauging during manufacture. It is not surprising that "Striker 1B" replaced it as part of the process of increasing production rate. "Striker 1B" is the common model with the two cutouts that are engaged by the striker assembly / removal tool.

-

Thank You to Bruce_in_Oz For This Useful Post:

-

01-08-2011 01:15 AM

# ADS

Friends and Sponsors

-

Last edited by jmoore; 01-08-2011 at 11:21 AM.

-

-

Off the subject a biut, but going back to Clav and the ISOD testing of old UK Milspec parts. We still had this testing facility at Portsmouth Poly during our metallurgy phase and we often discussed whether the impact ball was doing just what you DONT want to do. Albeit that it only left a small but measurable crater. But in stressed steel terms, it's no more than another stamp!

Milspec parts. We still had this testing facility at Portsmouth Poly during our metallurgy phase and we often discussed whether the impact ball was doing just what you DONT want to do. Albeit that it only left a small but measurable crater. But in stressed steel terms, it's no more than another stamp!

Our Belgian (or spanish or even portugese) made Browning L9 A1 slides crack at this point too. I put in a paper......... you know the sort, 'low ranking Officer suggests' (and a Territorial/CMF/National Guard equivalent to you colonials and antipodeans.......) and, and, and onwards and upwards it goes. Anyway I gave all the technical blurb and suggested that since a new slide now cost more than the original complete pistol, these could be easily repaired by tig ( it's a bit more complicated than that.....) and even over-plated with a steel outer at no detriment..... I don't know where it went, it came back for a further comment once, in about 1989. Being an eternal optomist, maybe it's still in transit somewhere. But on the other hand............

GREAT thread. I wish I was still teaching........

-

Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

[QUOTE=GREAT thread. I wish I was still teaching........[/QUOTE]

You are. Your just not getting payed for it.

-

-

Advisory Panel

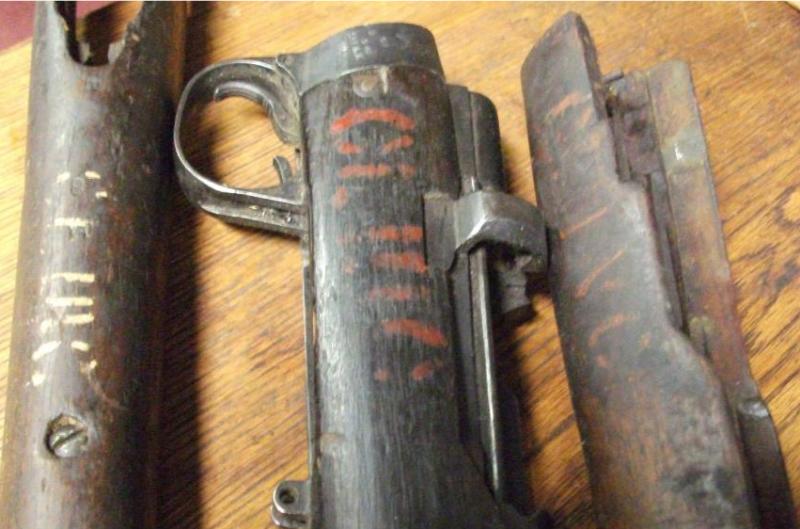

I wasn't sure about which thread to put these pics. As I do not have any accompanying information other than it is a DP rifle, maybe it's better off here as a failure, albeit on the head of the operator....

Attachment 18785

Attachment 18784

-

The Following 2 Members Say Thank You to Son For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Interesting photos. Out of all of them maybe the worst (since it's so common compared to most of these) is the one J. Moore posted of the "usual" split forend from someone's attempt to disassemble without knowledge of how to do so.

I have also seen bent and "repaired" stock bolts to add to the list (no pics).

-

Originally Posted by

Son

I wasn't sure about which thread to put these pics. As I do not have any accompanying information other than it is a DP rifle, maybe it's better off here as a failure, albeit on the head of the operator....

I think it's a great addition. At least it's easy to identify the root cause of the problem!

-

-

-

-

Legacy Member

Originally Posted by

Bruce_in_Oz

Remember that early SMLEs used a striker that had a lug which lined up with a notch in the rear of the bolt head. This was to ensure that if the bolt was not closed fully, the striker could not ignite a cartridge and do some serious damage.

The lug on the firing pin & the notch in the bolt head are aligned the moment you clip the bolt head down onto the bolt head rail, neither the bolt head or the firing pin rotate while working the bolt, if the bolt is not closed properly when fired, it either closes fully itself or go's into the "half cocked" position.

-

-

Link to CMP "s thread which shows a curious No.4 Mk.I with an even more curious fractured bolt catch :

"s thread which shows a curious No.4 Mk.I with an even more curious fractured bolt catch :

https://www.milsurps.com/showthread.php?t=28360

See post #8 for a close up view

https://www.milsurps.com/showthread.php?t=28360

-

PM

PM