-

Head Moderator

(Founding Partner)

Site Founder

Originally Posted by

jmoore

Ummm...???

As far as freeplay, 2mm ought to do. BUT, it might do to paint or otherwise lightly color the close fit areas to check for rubbing during the firing sequence.

I'm just going by what you posted here:

Originally Posted by

jmoore

As far as front band fit, it needs to make no contact on it's rear face with the front of the stock. It also needs to have ~3-5 lbs tension between the lip and the bottom of the stock and be well centered. The handguard should not touch the stock. The triggerguard should take some force to close. There's lots more, but those are good starting points.

-

Thank You to Stevo For This Useful Post:

-

04-03-2013 12:33 PM

# ADS

Friends and Sponsors

-

Head Moderator

(Founding Partner)

Site Founder

Originally Posted by

Patrick Chadwick

So shave the aluminium. If you do not have a multiple-axis fully programmable milling machine and a tame programmer - why, just try a FILE. Yes, it's slow, but you should only be needing to take off a matter of hundredths of an inch, unless something is seriously bent. The usual criterion for barrel-stock freedom is being able to slide a postcard around everywhere without it binding. I don't see any need for 2mm clearance all round - or have I misunderstood something?

Anyway, I see that you now seem to have made the necessary adjustments. Good luck at the range!

Patrick,

I do know how to run a file. Given the choice between removing material from a $400 handguard or a $100 stock to accomplish the same goal, I'll take it off the stock first.

I should have taken some pictures of it as well. There was considerably more than hundredths of an inch that needed to be removed, and from more than just the edge.

-

-

Originally Posted by

Stevo

I'm just going by what you posted here...

OK, then! All on the same page I reckon.

The main oddity to this bedding is the tension is reversed from the usual direction (on bolt actions, etc.) of the forestock pressing upwards against the bottom of the barrel. Here the forestock exerts downward tension against that little lip.

-

-

Head Moderator

(Founding Partner)

Site Founder

-

-

Originally Posted by

Patrick Chadwick

The usual criterion for barrel-stock freedom is being able to slide a postcard around everywhere without it binding. I don't see any need for 2mm clearance all round - or have I misunderstood something?

Yes. Misunderstood the addition of a midlength ported gas system hung by easily servicable, but not accuracy enhancing, means to a lightweight barrel connected to an even more easily disassembled action that is barely mated to flexible stock. About as not like a bolt action rifle as is possible whilst still remaining fairly "traditional" in role and contruction.

Misunderstood the addition of a midlength ported gas system hung by easily servicable, but not accuracy enhancing, means to a lightweight barrel connected to an even more easily disassembled action that is barely mated to flexible stock. About as not like a bolt action rifle as is possible whilst still remaining fairly "traditional" in role and contruction.

The Garand's gas system, being far further forward, has less opportunity to disrupt things in a dynamic manner whilst the bullet is still in the barrel. It also has much more action support in the stock due to it's longer and thicker legs than the M14 . Both have very light action bodies which receive firing recoil impact, plus bolt rearward and forward impacts during the loading cycle. Even a well glass-bedded, double lugged M14 action's heel will flex upwards over 0.004-0.005" off the stock when the bolt hits!

. Both have very light action bodies which receive firing recoil impact, plus bolt rearward and forward impacts during the loading cycle. Even a well glass-bedded, double lugged M14 action's heel will flex upwards over 0.004-0.005" off the stock when the bolt hits!

There's more! Off axis flexing due to the assymetrical nature of the op rod, mid band centering, op rod to gas piston positioning rotationally, as well as longitudinally, gas piston to gas cylinder fit, spline tightness, Non uniform stock to action fits amongst and even within the various commercial action manufacturers, damping effects of various barrel lengths, weights and attachments- and that's just things off the top of my head.

These rifles can shoot well, but they can also be quite the nightmare. Personally, I think it's worth the trouble. Too bad it's far too late for a third generation with all the lessons learned over the past fifty years incorporated into a new military platform.

Last edited by jmoore; 04-04-2013 at 12:48 AM.

-

The Following 2 Members Say Thank You to jmoore For This Useful Post:

-

Advisory Panel

Originally Posted by

Stevo

I do know how to run a file. Given the choice between removing material from a $400 handguard or a $100 stock to accomplish the same goal, I'll take it off the stock first. I should have taken some pictures of it as well. There was considerably more than hundredths of an inch that needed to be removed, and from more than just the edge.

Ok, sorry, I did indeed misunderstand something. That's an expensive handguard! But in such an expensive setup, I am surprised that so much material needs to be removed, from wherever.

-

-

Advisory Panel

Originally Posted by

jmoore

There's more! Off axis flexing due to the assymetrical nature of the op rod, mid band centering, op rod to gas piston positioning rotationally, as well as longitudinally, gas piston to gas cylinder fit, spline tightness, Non uniform stock to action fits amongst and even within the various commercial action manufacturers, damping effects of various barrel lengths, weights and attachments- and that's just things off the top of my head.

Thanks for the explanation. It sounds as if the Garand is, in fact, easier to deal with. By the time the Garand piston can really upset the dynamics, the bullet is on its way. But a friend has one of these M14 shorties, in GI configuration, which shoots very accurately, without any of this bother, which is why I made my suggestion of going back and starting over, on the old engineering principle of "If it's not there, it can't go wrong"

shorties, in GI configuration, which shoots very accurately, without any of this bother, which is why I made my suggestion of going back and starting over, on the old engineering principle of "If it's not there, it can't go wrong"

-

-

The shorties tend to be harder to sort when they're not happy. But the thing that drives one to madness is that some do very well indeed!

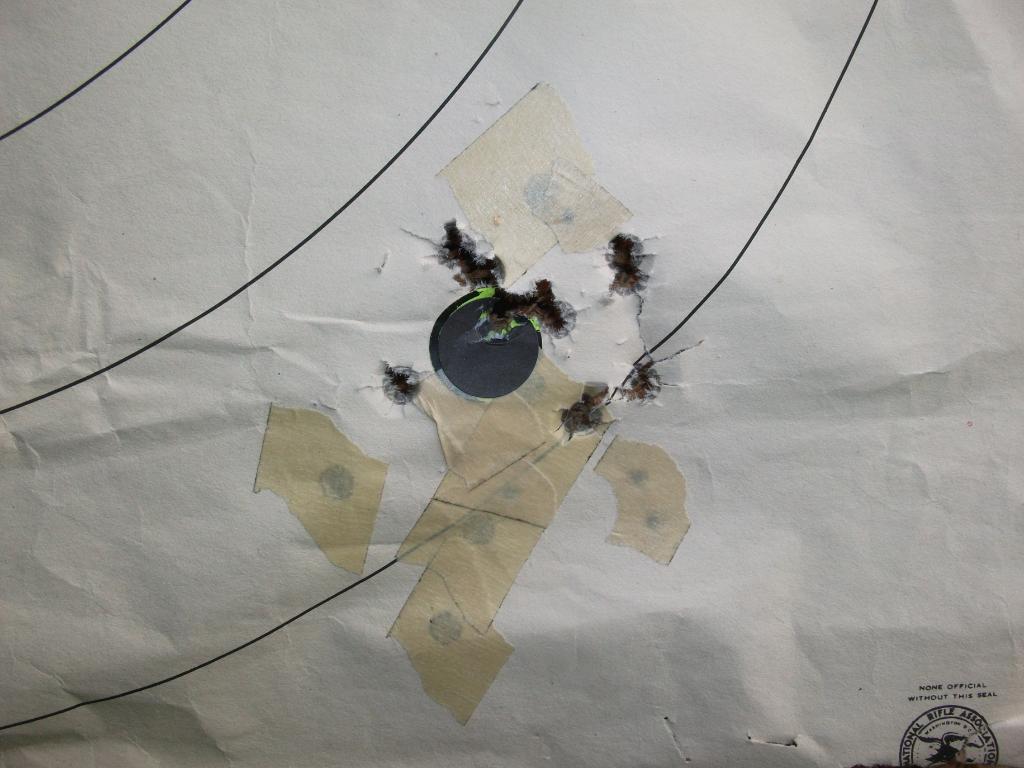

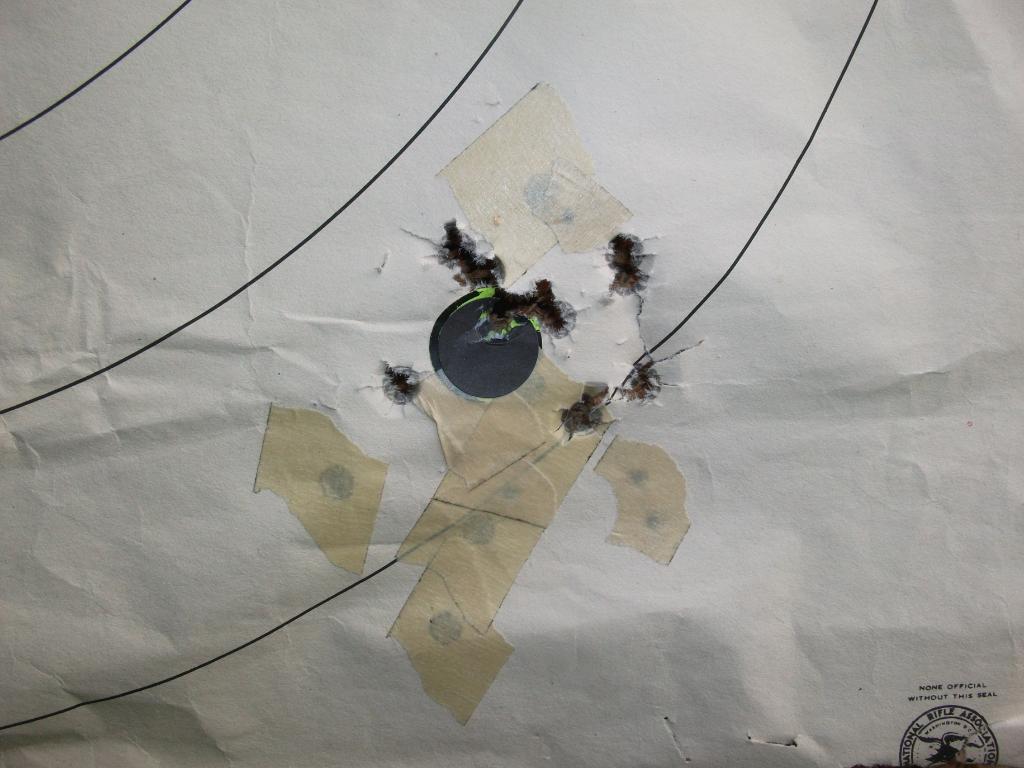

This one in a SAGE stock is fairly acceptable with no fancy barrel or any sort of fine tuning.:

3/4" dot at 100yds (Usual jmoore used and pasted multiple times over several sessions target.)

But a lightweight it's not. The military versions have done quite well as DMRs. As a GP rifle, probably not my first choice, but it is an evolutionary step towards modernizing the platform.

ETA: Note that the SAGE system locks the action and the barrel at the mid band quite rigidly into the chassis. In this case, the front end has no support at all. Something that's just not workable in a conventional stock, because the front band lip is essentially the "front action screw" for a bolt action. There's nothing much else to keep the barreled action from trying to rotate up and out of the stock under recoil. (Not altogether literally, but maybe it conveys the idea.)

Last edited by jmoore; 04-04-2013 at 02:53 AM.

-

The Following 2 Members Say Thank You to jmoore For This Useful Post:

-

-

The Following 4 Members Say Thank You to Stevo For This Useful Post:

-

Range report since the blizzard?

-

PM

PM

Misunderstood the addition of a midlength ported gas system hung by easily servicable, but not accuracy enhancing, means to a lightweight barrel connected to an even more easily disassembled action that is barely mated to flexible stock. About as not like a bolt action rifle as is possible whilst still remaining fairly "traditional" in role and contruction.

Misunderstood the addition of a midlength ported gas system hung by easily servicable, but not accuracy enhancing, means to a lightweight barrel connected to an even more easily disassembled action that is barely mated to flexible stock. About as not like a bolt action rifle as is possible whilst still remaining fairly "traditional" in role and contruction.