-

FREE MEMBER

NO Posting or PM's Allowed

Question related to rebuilding draws

-

01-19-2014 03:58 PM

# ADS

Friends and Sponsors

-

The direction of the grain is one of those things. You are taught to do it as per the grain of the fore-end while you're learning the job in the classroom but out in the REAL world, you do it as per the way that the older and more experienced Armourers tell you. Grain to run parallel to the plane of the draws in the rifle body.

If it was my rifle I'd clean off the rear of the fore-end and smooth off the face of the butt socket as it LOOKS like there's some protrusions there. Rust maybe? The fore-end must be drawn up tight to the butt socket. That's why they are called draws!

JUse the old peg holes but slightly oversize and made of oak

-

-

-

FREE MEMBER

NO Posting or PM's Allowed

Thanks Peter. Those two spots that are circled are the only two points that I could see were bearing on the socket. I'll take a file and slowly smooth the whole thing up.

-

FREE MEMBER

NO Posting or PM's Allowed

So before I glue this in, have I got it right?

-

FREE MEMBER

NO Posting or PM's Allowed

What glue?

Stock looks very oil impregnated to me?

-

Looks right to me but only YOU know if it's a good tight fit. As per SSJ above. Make sure that the fore-end is degreased as best you can too

-

-

Advisory Panel

Make sure that the fore-end is degreased as best you can too

I suppose everyone has their own technique. I use a micro blowtorch to carefully heat up the wood. This causes the oil to bubble out, and then it can be mopped up with some tissue paper. You can singe the wood a bit, but the resulting surface is quite dry and gives a very good adhesive bond.

-

The Following 2 Members Say Thank You to Thunderbox For This Useful Post:

-

Legacy Member

Hardens the wood too, I like that idea TB. Definitely a big boy technique....

-

-

FREE MEMBER

NO Posting or PM's Allowed

Thanks for the idea TB. I think I'll us a heat gun instead though. So far I've hit the area with several sessions of Circa 1850. That got most of the surface oil off, but I did want to get some more oil out of the area first. (Just spent 1 1/2 hours doing some internet searches.)

-

Legacy Member

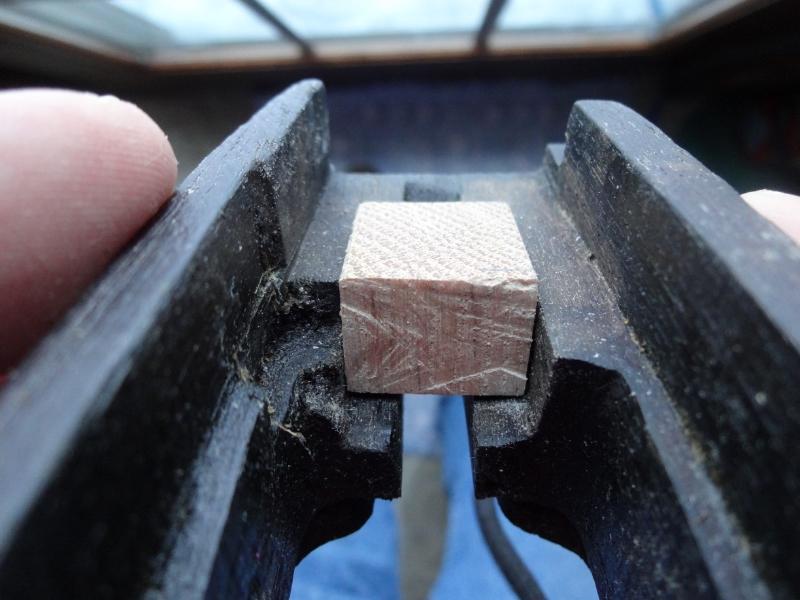

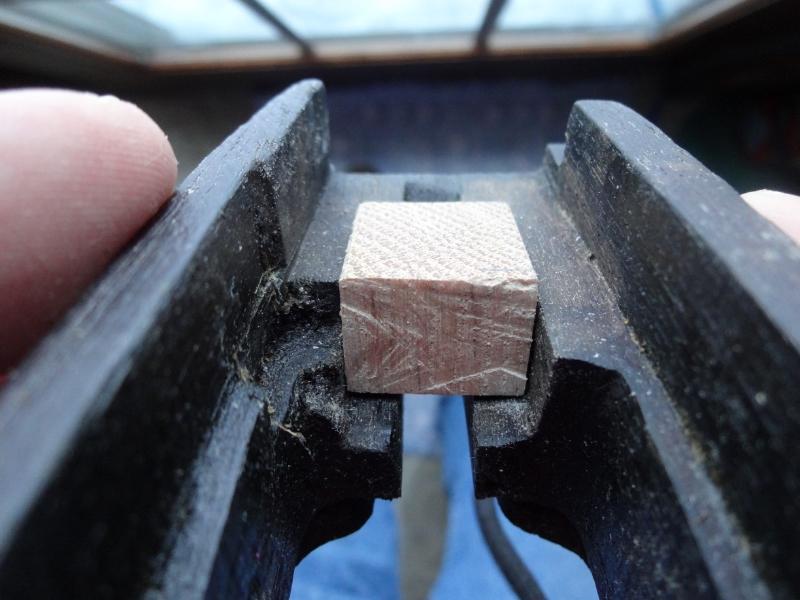

While we're on the subject I'm going to sneak in with my own question. I have at least one of these repairs on my "to do" list and was thinking that the repair block should be laid out with the end grain running more or less perpendicular to the stock center line as I've tried to illustrate. Is this correct? Am I nitpicking?

Last edited by Steve H. in N.Y.; 01-21-2014 at 06:50 PM.

-

’s article on stocking up a forend at least 5 times now, plus numerous other threads at CGN and here. I feel pretty confident in being able to rebuild the draws.

Register To Reply

Register To Reply