Latest update:

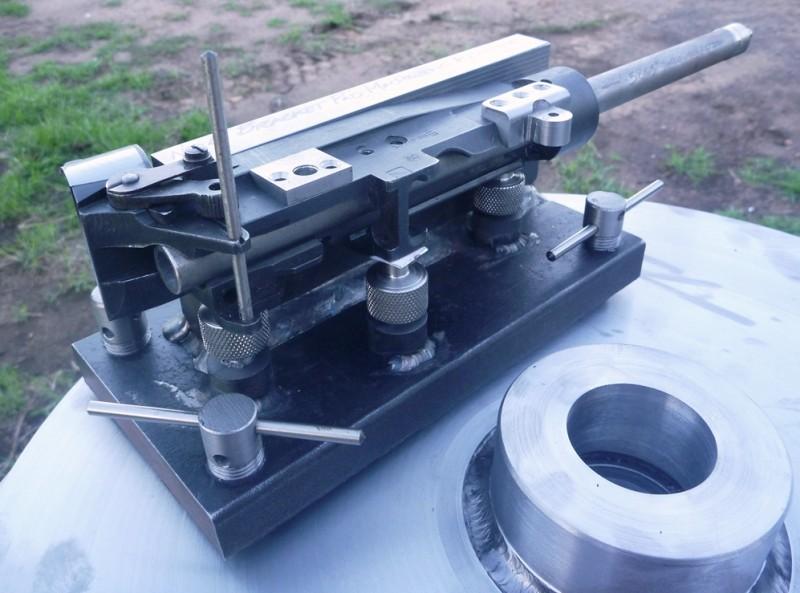

Have finished the fixture to hold the action, as the pads are installed and the interfaces for the telescope bracket are machined.

Its bit of my own variation on the other fixtures I'd seen on the forum - should be plenty rigid & finely adjustable for collimation.

Will work with either the "plunged shell mill" method of forming the spigot or the radial method (though bringing the whole thing into line with the dividing head spindle axis, will no doubt be "fiddly").

- the levelling feet will allow the bolt way centreline & rear sight pin axis to be plumbed up, and the fixture is in turn dogged down to the faceplate.

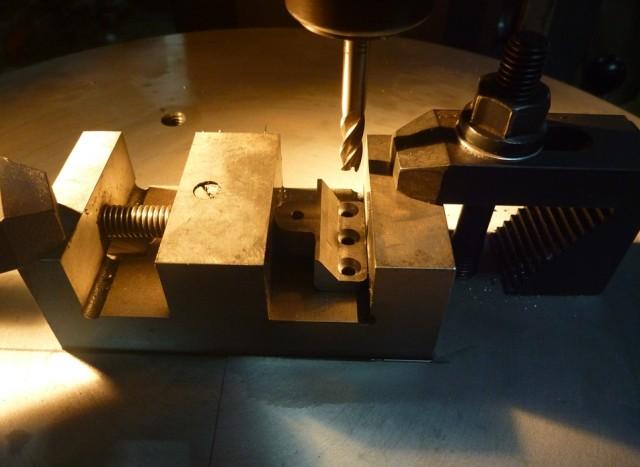

- the jacking screws bare against the side directly resisting the thrust forces of the drilling/milling operations and in combination with the securing points on the vertical face contribute to the overall rigidity of the work piece. the mandrel itself just rests in place and is a very neat slip fit in the ways

- The faceplate is underway, its been flame cut from 25mm PL x ~400 Dia (rougly as large as I could swing without removing the gap bed - should clear the column of the milling machine by 30mm). Tigg'ed an ASAB bar boss on to it, now just have to go and skim it all true and thread it M45x3.0 to accept the dividing head spindle. - the whole thing should be a "goer" after this and I can get on with the actual project itself rather than all the ancillaries.

Information

Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM