-

Contributing Member

Hard to say about the flywheel nut at first glance it looks like something may have bounced around in there but then it makes me think of timing marks that were used with a pointer because of how they're spaced. The man who mentored me some for engine building raced English bikes and used to rebuild some for those who came looking. He would replace those bronze bearings by heating/expanding the case and then fitting them in on the Brits. I learned some static timing on BSa motors that were void of timing marks so you had to be right on twin or you bust a piston easy or melt one out with early or late spark and too lean. I don't know if that could happen on a single its been such a long time I should just be quiet. English bikes were a work of art in my mind compared to the hd which was center stand roll rear tire to gap opening tdc valves closed then bang but cool too in they're own right. I'm going to get another (English) one day after looking at all this.

-

-

03-09-2017 10:46 AM

# ADS

Friends and Sponsors

-

Brian I would say the marks are caused by the lack of a spanner at some point, as for the timing its very basic, need to check and set points first, points should start to open when fully advanced and the piston is 3/8 " before TDC.

The technical part is using a piece of paper between the points as this should just be able to pull out if all correct..........

(on the subject of points, I could never find the correct points for my Land Rover 90, it was only when I was talking to guy in an old spare parts place, that he told me why....... it turned out that Lucas was on strike at the time or a problem with part of the production so couldn't supply Land Rover, Land Rover didn't hang around, they just used a bosch distributor instead....... )

-

-

-

Legacy Member

Yep, that nut was undone and done back up with a hammer and chisel.

-

-

Used a chisel because he didn't have a thin walled BSF socket to fit. The problem with a LOT of BSF sizes is that the generally 'useable'(?) AF or metric socket sizes are a poor substitute. But good for rounding off the apex of the nut or better still, cause you to rapp your knuckles. Ouch! Having a Norton, been there and done it........

-

-

Contributing Member

I got it, someone didn't have a wrench/socket combination to remove the nut (spanner) and then staked it. Is there a plug in the case that can be removed to insert a lock or pin into the flywheel at 3/8 BTDC after you roll it over a few times? I, started to remember the tools Mr Ronnie had they were fantastic and were-kept in a separate tool box from the others and were Whitworth which were a complete mystery to me because of the markings on the open end side.. Some were factory items and very delicate degree wheels and timing indicators that were maker specific but fork wrenches and frame gauges/bushing drivers were often made by him. I was so lucky and learned about something that was completely foreign and out of the ordinary to most in the area that I live and grew up in. These days there are so many that $15000 has made them a biker but I don't see them running that stuff off-the road and cutting through the woods or anything and then back up again down a muddy lane. That is a most rewarding project and an indication of longevity and quality that is not often appreciated these days and nearly lost because it is possible to repair your parts most of the time with some ingenuity. Plus, whatever is in those bottles and that lathe will be a big help too. I was never smart enough to figure out some of the electrical problems and had to use the wire cutters alot for lack of parts/drawings here that were out of my reach.

---------- Post added at 08:39 AM ---------- Previous post was at 08:31 AM ----------

Used a chisel because he didn't have a thin walled BSF socket to fit. The problem with a LOT of BSF sizes is that the generally 'useable'(?) AF or metric socket sizes are a poor substitute. But good for rounding off the apex of the nut or better still, cause you to rapp your knuckles. Ouch! Having a Norton, been there and done it........

I had a guy from the old country yelling bloody murder at me to get the Grover when I was a kid and had no idea he was using that as a euphemism for a specific tool, I really still dont know what the H#ll he was going on about.

-

-

-

-

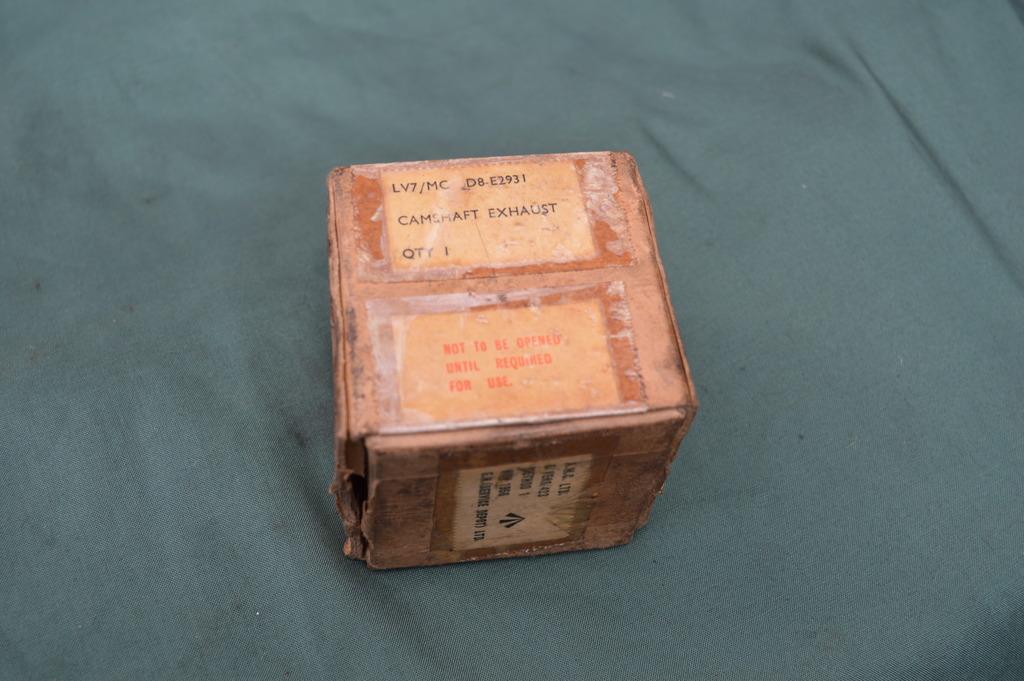

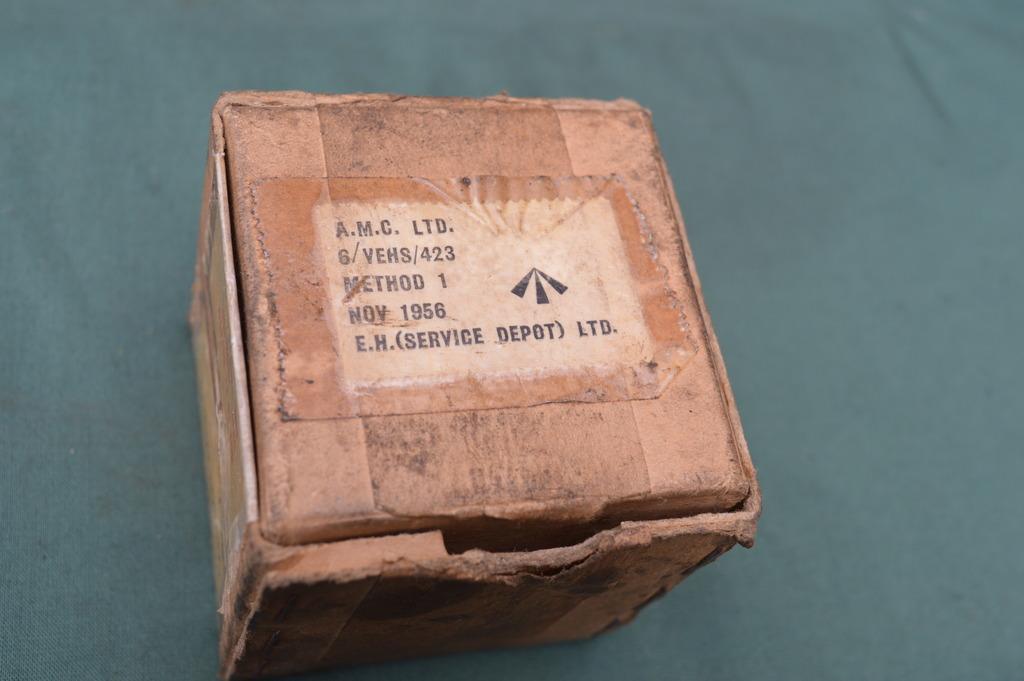

The packing note on the bottom of the box relates to the method of packing - as in METHOD 1 - long term preservation, the packers logo - AMC Ltd and their depot code EH, date of course and that particular contract number - 6/vehicles 423. This was so that any defects could be traced back

-

Thank You to Peter Laidler For This Useful Post:

-

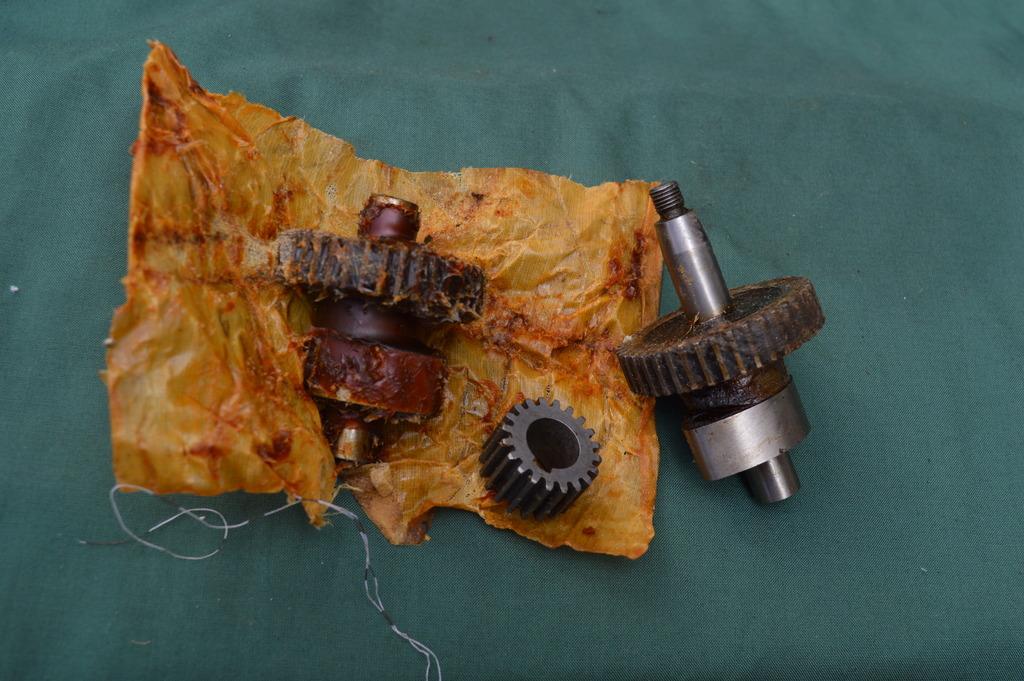

Thanks Peter, "Method 1" has certainly paid dividends , there is something about opening a 61 year old package, I guess some are put of by looking at stuff out of the box and see the dark areas on the wrapper and thinking rust........ the actual cams are a scarce item now and I got a really good deal on these, saved around £100 by shopping around.

The supplier of some other bits I was talking to yesterday said the preservative that was used on some of the tappets he had, had the opposite effect and most of the stock was a write off...... (but I'm getting a few freebies in case they can be salvaged)

-

-

Legacy Member

Oil return?

Whatever happened to traditional British "positive crank-case drainage"?

"positive crank-case drainage"?

-

-

Originally Posted by

Bruce_in_Oz

Oil return?

Whatever happened to traditional

British

"positive crank-case drainage"?

Still available on most models.......bit like a Land Rover if its not leaking, then its got no oil in it.

-

PM

PM