-

Legacy Member

How Did Long Branch rifle their barrels?

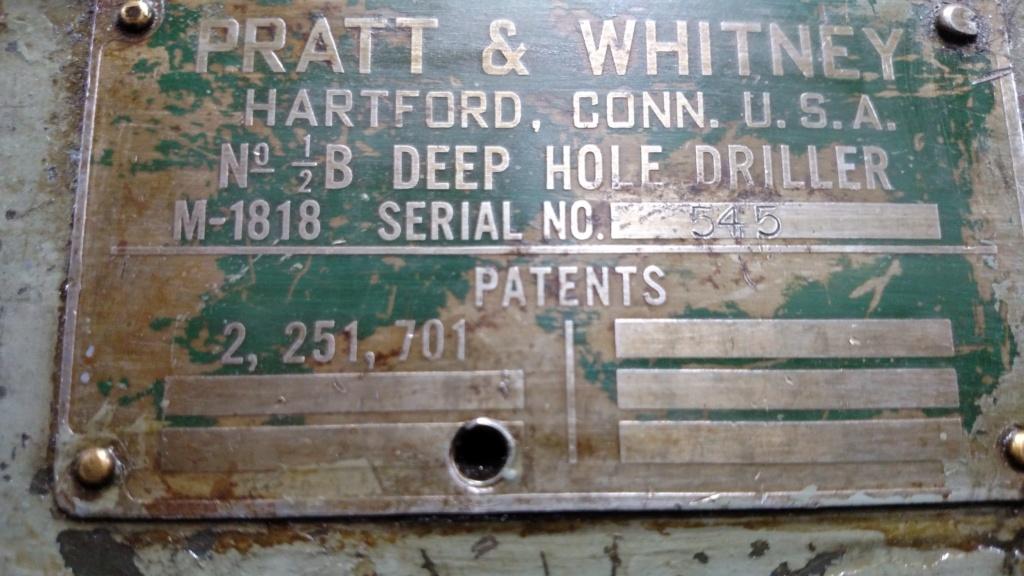

I just took a look at my 1950 Long Branch barrel with a bore scope. After spending most of last year trying to get the carcass of the former Montana Rifle Company up and running again, making barrels. The drills and reamers left behind by Remington/Montana Rifle company are 1930's Pratt & Whitney's, surplused from Springfield Armory, many of which still have the brass 'Springfield Armory' and 'Department Of War' brass tags on them. That's for context as I wonder what machinery and method Long Branch used in the 1940s/1950 to drill, ream, and rifle barrels.

Anyways, to the best of my knowledge, this Long Branch has never been issued, so it's total round count would be any rounds fired at the factory prior to getting coated for storage, followed by 20 rounds of Greek HXP by me, and then more recently five rounds of powder coated cast bullets, properly fitted to the leade/throat, and fired with 'the load'.

I did lead lap the barrel under the supervision of my gunsmith buddy who was building winning benchrest and fullbore rifles back in the 70's when I met him - when he wasn't placing and occasionally winning in those disciplines. So I couldn't have cocked up the lapping of the barrel too much if I did at all - the barrel felt wonderfully smooth when I was done; all the noticeable tight and loose spots when I started had disappeared.

So now with a borescope in my hands - and six months of looking down just completed barrel blanks - I looked at my Long Branch.

There's still reamer marks across the lands; they look like the surrounding steel has been polished and there's no sharp edges to the reamer marks, but they're still there. There what appear to be rough striations running at the bottom of the grooves; they look a little dulled rather than sharp. And there appears to be what appear to be small pits along this, with what almost looks like smoothed off very shallow gouges. Those small pits a legacy of a proof round that was then sealed in with the preservative applied afterwards?

And somewhat to my amazement, there was still an evident copper wash in places, polished to a very nice shine. Two patches of Sweet's, and the copper disappeared completely.

I'm not thinking my lead lapping was a dismal failure. I didn't have a borescope when I started to see the appearance of the bore at that point, nor to see the bore after the lap felt consistent from muzzle to throat. I'm surprised that the copper wash was still there, but I don't know how many microns (or whatever) thick was left in those spots.

What surprises me is the remaining striations and reamer marks after a day of lapping with successive grits of Clover compound. The reamer marks look as bad as the unmaintained and badly worn Pratt & Whitney's left behind as yet another bearing was packing it in. MRC button rifled; I never saw a button rifled barrel out of that plant that had striations in the bottoms of the grooves like my Long Branch. Not even remotely close.

Sooooo.... how did Long Branch do their rifling in 1950?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Last edited by Rick; 01-24-2021 at 02:59 AM.

-

-

01-24-2021 02:56 AM

# ADS

Friends and Sponsors

-

Advisory Panel

Some info from our past threads here... I don't think anyone mentions the manufacture of the machines or type.

http://www.milsurps.com/showthread.php?t=1682

https://www.milsurps.com/showthread.php?t=45997

-

-

-

Advisory Panel

Your best bet may be to view "A Trip Through Small Arms Ltd" and as many photos as you can find of the Long Branch plant and see what you can see.

Many years ago I had some broaches said to be out of Long Banch, but that was before digital cameras and I don't think I took any photos. You will have heard that the six groove Long Branch barrels were rifled with the same broaches etc. as LB Bren barrels.

I don't know if anyone knows exactly why; it may have been just an experiment, but it occurs to me that the WWII era broaches and machinery may have been getting pretty worn by 1950.

Would production have ramped up during the Korean War, and would new tooling and machinery have been set up? Hard to say, but a new rifle and a new calibre was already in the wind by 1950, and with huge stocks of WWII production on hand, why refresh the No4 machinery and tooling?

This might explain the use of the Bren tooling: it was in better shape than the five groove and the latter wasn't going to be replaced?

Warren I hope will comment on this.

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

-

Legacy Member

How well did it shoot? Before and (if done) after?

-

-

Legacy Member

Originally Posted by

enbloc8

How well did it shoot? Before and (if done) after?

I stopped when almost done lapping (because I was getting bored after six hours of repetition), went outside and shot a group, but the scope in the S&K mount was off by then, and it was back to the P-H No.4. So it was a comparison of groups shot with a 24x scope, versus a group shot with a target aperture.

I wasn't as precise in shooting the group as I would usually be when shooting test groups. But the group with the same 1969 HXP ball used to evaluate with the scope on was more than something to be happy with. When warmer weather arrives, the S&K with a scope and another 10 shot group at 300 yards to compare to the original evaluation grouping should tell me if I gained everything from all the lapping effort.

I did the lapping because of an intention to use it as much as a cast bullet rifle as with jacketed bullets. This was all prior to the advent of powder coating cast rifle bullets.

I powder coat all cast bullets intended for rifles now, so lapping probably won't be as beneficial to my cast bullets now as it would have been before when I was using hard lube. The rounds to test that accuracy are sitting here waiting for better weather as well. Unlike the Greek HXP ball, I don't have baseline cast bullet loads to do a before and after comparison with.

Last edited by Rick; 01-26-2021 at 06:21 PM.

-

-

Legacy Member

-

Thank You to Rick For This Useful Post:

-

Legacy Member

Originally Posted by

Surpmil

I don't know if anyone knows exactly why; it may have been just an experiment, but it occurs to me that the WWII era broaches and machinery may have been getting pretty worn by 1950... This might explain the use of the Bren tooling: it was in better shape than the five groove and the latter wasn't going to be replaced?

Again, eyeballing the striations running in the bottom of the grooves of this five groove rifle, thinking that at least the cutters were getting worn seems to make sense. Still, sharpening of cutters, no matter how worn the machines itself may be, is a normal operation during barrel manufacturing (or at least it is now). So the striations I'm looking at can just as easily be a result of the last barrel rifled before a change of broach cutter to a fresh one. Or a barrel rifled by a broach that should have been changed out long before.

But there's also those reamer marks across the lands; still there after lapping.

What I don't have right now is the other 1950 Long Branch rifles I bought with this one that I kept. If I'd had a borescope back then, I would know if this is just normal, worse than normal, better than normal, etc. Ditto for what the barrel looked like before I started lapping. I know what the barrel felt like during the first passes of lapping, versus what it felt like afterwards, but that's just subjective.

At the bottom of it all, my curiosity aside, this barrel shot extremely well before I lapped it for cast bullet use and it will group at least as well now, if not better. So all of this is just my curiosity after looking inside the barrel after lapping and wondering what it looked like before I started.

-

-

Advisory Panel

Those rifling machines welded up out of HSS don't look too inspiring I agree, but obviously they did the job and I assume that is because the barrel itself is guiding the broach/button?

The old P&W deep boring machines, now those I wonder about: they don't look like they've had a rebuild since new? Were the ways ever re-ground?

If I understand the process correctly those determine whether the hole that becomes the bore is the true to the blank or not, but maybe that is that all taken care of when the blank is profiled between centers before rifling?

Last edited by Surpmil; 01-27-2021 at 10:23 AM.

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

-

Legacy Member

Originally Posted by

Surpmil

Those rifling machines welded up out of HSS don't look too inspiring I agree, but obviously they did the job and I assume that is because the barrel itself is guiding the broach/button?

Pretty much: the buttoning rod is pulled through the drilled and reamed blank, coated inside with a slippery soap. More or less self centering.

The old P&W deep boring machines, now those I wonder about

: they don't look like they've had a rebuild since new? Were the ways ever re-ground?

I found no documentation while searching for service manuals, etc that said anything about their history of servicing. Pratt & Whitney did a spectacular job of ignoring any and all email and phone inquiries about any documentation they might have. Which is kind of remarkable, considering how many barrel makers STILL use them, particularly custom barrel makers. Dan Lilja also in Montana being one, if I remember correctly.

The old MRC staff we found and I talked into coming back (or maybe they wanted to come back anyways) told us that they were told "run 'er till she breaks" first by Remington during their ownership, and then again by the new MRC owner group who bought it after Remington dumped it. So yeah, they're in sad shape, the running gear even more than the ways.

If I understand the process correctly those determine whether the hole that becomes the bore is the true to the blank or not, but maybe that is that all taken care of when the blank is profiled between centers before rifling?

After doing QC/QA on hundreds of barrels prior to shipping, I never saw one that was off-center to the round barrel blank. Or at least, not one that could be determined to be off center by eyeball. At regular intervals, a newly drilled barrel off a drill is mounted between centers on a test fixture and checked for runout with dial indicators. When I left we were using a +/- of about .005", if I remember correctly .

We were not doing any profiling. We had more than our hands full producing rifled barrel blanks in the caliber requested. I believed that was an enormous mistake, particularly when it would have taken a comparatively very small amount of additional time to place a rifled blank in one of the unused multi-axis CNC machines and end up with a profiled, drilled, threaded and chambered finished rifle barrel to sell.

So sell the blanks for somewhere around $32 each, depending on caliber and length; versus several hundred to sell a finished barrel ready to go.

Which is one of the reasons I'm not there anymore. Stuff like that, while sitting on a gold mine like that in a time of demand like the last year and now. Those machines desperately in need of a rebuild and needing time and constant adjustments to turn out a finished drilled and reamed barrel would be much easier able to handle making perhaps only 5,000 barrels a month to be used to produce finished barrel. Versus productivity rates of 35+K a month of rifled barrel blanks.

Sadly, I doubt my friend who bought the carcass of MRC will still be operating by the end of next month. Insisted on taking too much of a bite with the condition of the machinery he got with the purchase.

Really sad. I used to sit there thinking what it would cost to tool up one of the unused machines to do simple .303 barrels of optimal bore and groove diameters, or even replica Lee-Enfield and Ross Rifle barrels.

-

The Following 2 Members Say Thank You to Rick For This Useful Post:

-

Advisory Panel

So the company was being milked by the "ownership group" for max return now and to heck with the future? Totally typical for North America now; the stock market and the investment funds are destroying what overseas competition doesn't, but capital doesn't care, it will just go somewhere else...when you stop and look at these endless ownership shuffles, management buyouts, "reorganizations" etc. etc. you can see the wreckage everywhere: skill sets lost, plants and machinery gone. And the politicians don't know and don't care - but then of course neither does most of the population - they think they're in the First World "just because" as though GDP from junk bonds is the same GDP from durable goods! That's not what got us here, and it won't keep us here.

They say you can't fix stupid, that's history's job.

What a pity for your friend; hopefully individuals will pick up some of the machinery and start again. We'd all sure love to see some quality new barrels for decent prices. Thanks for sharing that information, most interesting.

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

PM

PM