-

FREE MEMBER

NO Posting or PM's Allowed

Man, everything I read here about these No. 5 forends has got me scared to death to try and take my No. 5 apart! I'm scared what I might do to it, and scared as to what I might find too.

-

10-22-2009 06:45 PM

# ADS

Friends and Sponsors

-

Legacy Member

Hereby hangs the catch with military rifles (and their ammo).

They are integrated into a logistical and administrative system that (mostly) works.

Military rifles are built to perform to a standard with a nominated ammunition set; ball as primary, tracer etc, very much secondary. Compare that to a commercial sporter: .22Hornet to .458 Win Mag, chrome moly or stainless, three action lengths, five barrel profiles, eight stock options, and then there are sights, and all combinations and permutations of the above.

If a soldier's rifle is not performing as advertised, it is placed in a repair system of spectacular size and scope. This is not your corner gun shop. This big gun shop only deals with a relatively tiny range of equipment compared to commercial operations but it has its own "pipeline" to the spare parts warehouses. Not only that, but ALL of the "customers'" weapons are "run over the pits" at least once annually, whether they have been used or not. It starts when unit "gun plumber" does an inspection on a problem weapon. He will swap out the dodgy bits and return it, or boot it up to a higher level facility if beyond his repair level as specified in the manuals.

These published maintenance instructions are to be followed to the letter; i.e. "if this, then that". Component "adjustment" is only allowed as per these instructions and, in these days of CNC, investment casting and injection moulded plastic, there is not much scope for that anyway.

So the nub is that our trusty old Lee Enfields are leftovers from a system from over a century ago. You cannot just write out a requisition for a swag of new parts for them and any repairs should be done as closely as possible to the original technique. As far as woodwork goes however, modern epoxies work very well if used correctly to repair cracks and splits.

Mr. Laidler 's notes and references are pure gold, as are the technical documents posted by Ed Horton and others.

's notes and references are pure gold, as are the technical documents posted by Ed Horton and others.

It is a bit scary; it is a bit "different" and they don't make them like that anymore, but it is worth the effort of doing it correctly

-

The Following 2 Members Say Thank You to Bruce_in_Oz For This Useful Post:

-

So I read the article by Peter Laidler and did the job, and it's come up beautifully. Thanks very much for the advice.

and did the job, and it's come up beautifully. Thanks very much for the advice.

Here are some pictures.

Will shoot it tomorrow, and if all good will peg it then.

-

The Following 12 Members Say Thank You to tbonesmith For This Useful Post:

Badger,

Black Prince,

bow,

bradtx,

henry r,

jmoore,

Joe O,

No4Mk1(T),

paulseamus,

Peter Laidler,

RJW NZ,

villiers

-

Ah, great to see an old fashioned Armourer at work again. Just like we used to do 'em - week in, week out, weeks at a time on the test range, bruised shoulders and torn elbows. A pleasure to see TBone and I hope that it's an inspiration for others

Has anyone got rid of their Ishy screw yet? Let's all see the result...., but only if it's GOOD!

Last edited by Peter Laidler; 11-20-2009 at 01:52 PM.

-

-

Banned

-

Rifle shoots well, will have to wait a bit to shoot some groups, today was standing at 100, and I didn't have time to shoot groups beforehand. But it all looks fine.

-

-

Just a quick update, I used the rifle in 200m comp today with some light loads of 174gn fmj's and the rifle performed very well, putting all the shots where they were pointed with the only major fliers being the result of a couple of case separations (This remington brass had done more than 15 reloads, and now it's dead).

-

Thank You to tbonesmith For This Useful Post:

-

BTW this rifle is now for sale in the WTS section of this site.

-

-

FREE MEMBER

NO Posting or PM's Allowed

I apologize if i'm not so handy but...if i have ,we say, 0,1 mm. clear from contact between fore end and socket, what i have to do? to patch more lenght draws and to sand fore end until it touches tight receiver socket or what else?

-

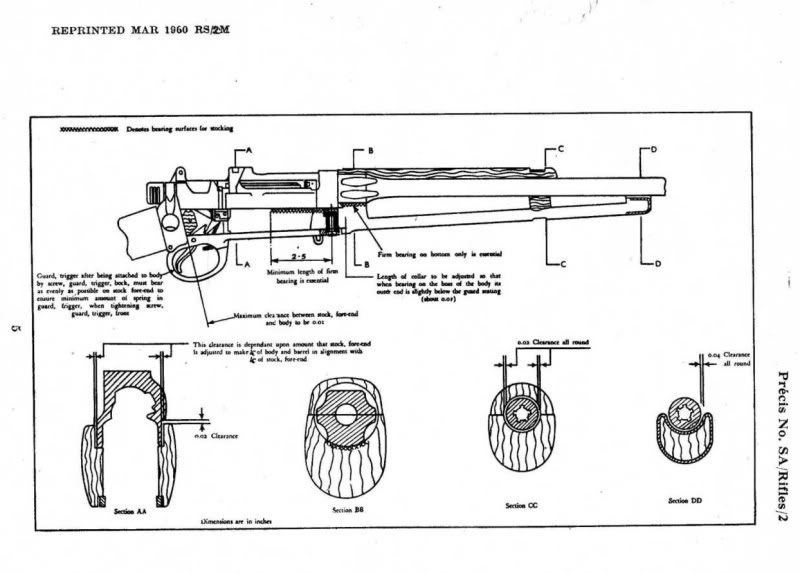

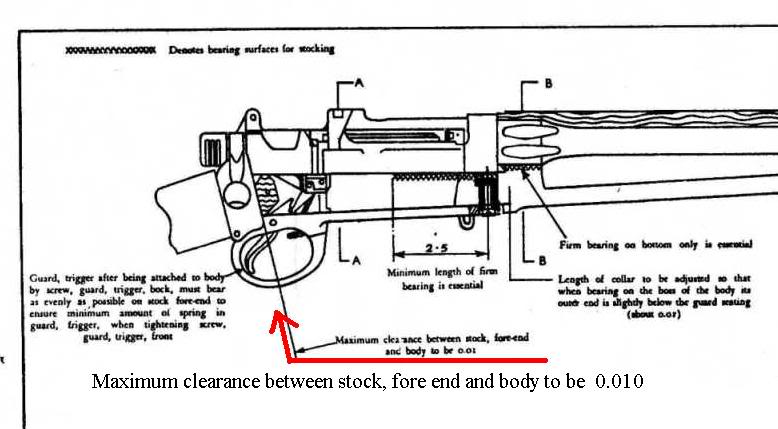

You can have up to .010" gap between the rear of the fore-end and the front face of the butt socket. If it is MORE, then you should patch the draws to decrease the gap by drawing the fore-end rearwards to close the gap right up to nothing. It must be a tight fit after refitting or patching the fore-end

-

Register To Reply

Register To Reply