Ireload2

Sorry YOU are wrong AGAIN ireload2, do you think I single source the material I put on the internet, do you think I believe 10% of the BS that is written on the internet by anyone with two fingers and a computer.

I worked 34 years at a military depot and the last 25 years were as a Master Level Inspector and the tech library was in the room next to me, over half my life has been devoted to manuals and Quality Control and I can’t believe how many times you have been wrong in these forums and have stepped in your own fecal debris.

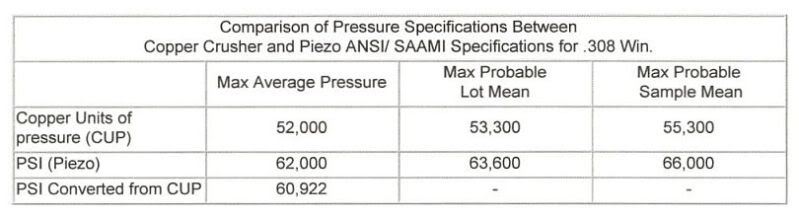

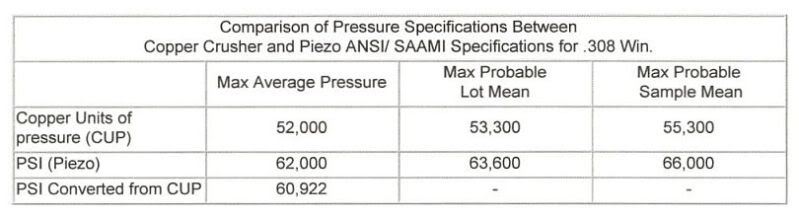

YOU do not know the difference between CUP (copper units pressure) and the transducer PSI method of measuring chamber pressures and what the actual differences are.

CUP reads as PSI and the transducer method reads as PSI, BOTH readings are PSI and the Army NEVER changed the way the manuals are written which are “copper units pressure” (CUP) reading in pounds per square inch.

I’m going to be very nice and explain this very slowly……….

Figures are rounded off

50,000 CUP = 60,000 PSI

52,000 CUP = 62,000 PSI

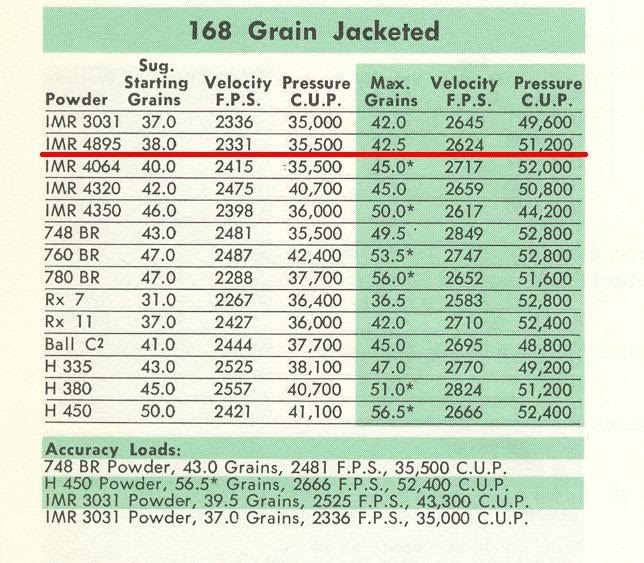

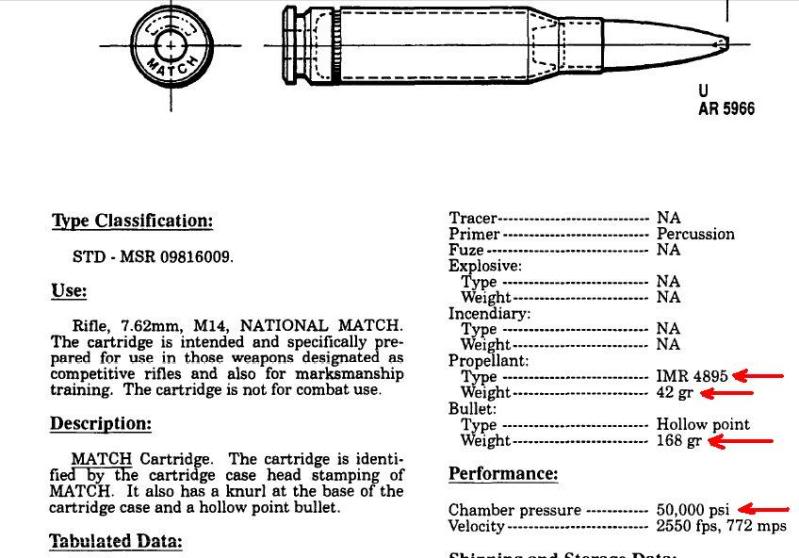

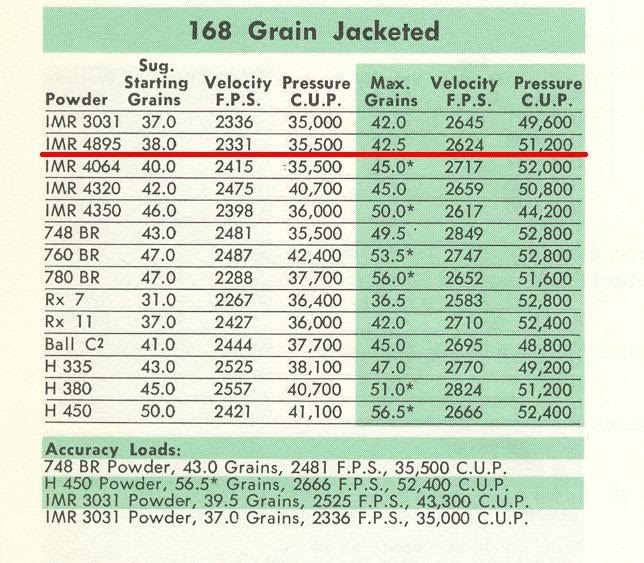

1968 Lyman reloading manual BEFORE the transducer PSI method, please note the IMR-4895 data for the .308 Winchester (42.5 grains at 51,200 CUP)

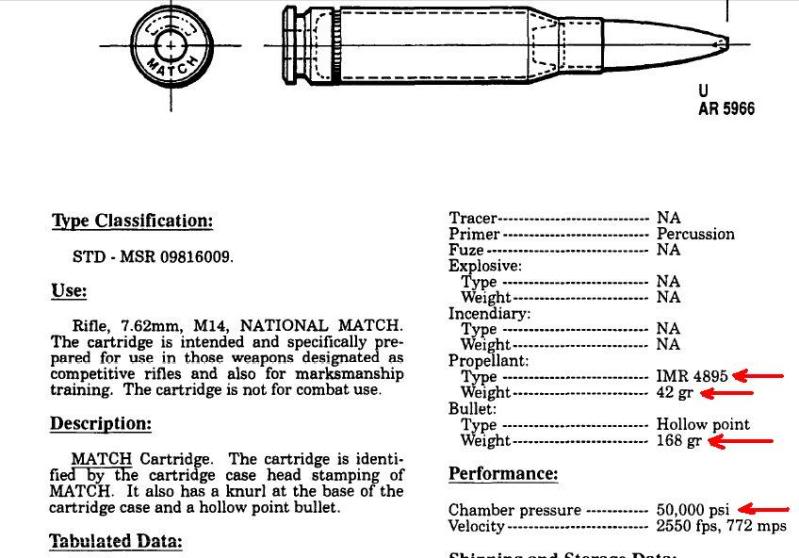

Army TM on ammunition for the 7.62 Match round (42.0 grains of IMR-4895 at 50,000 CUP) please note there is only one half grain of powder and 1,200 PSI difference between the military match load and the Lyman load for the same weight bullet.

Now how in the hell does half a grain of powder raise the chamber pressure 10,000 pounds by your bassakwards logic meat head.

Take your computer software for guesstimating bolt thrust and pressures and stick it in your ear and then go back to Varmint Al’s and re-read the sections on polishing chambers and the bolt thrust generated, THEN you will understand your computer program figures are off because of friction and the case gripping the chamber walls. On top of this Varmint Al’s muti-purpose $200.00 dollar software program would never compare to what we used at military depots.

And start cross checking and triple checking your information before you post information from garbage websites.

P.S. Please remember I told you I was never wrong and your not holding up well under pressure

(where it was clearly used regularly) and again in Germany

.

correctly observed, the pin holding the rear sight bolt was damaged (I bent it ... and then lost it while fitting a Parker Hale rear sight).

Register To Reply

Register To Reply