-

Contributing Member

Rings Hollow?

WRA could not get the steel it needed, but they had a large stock of chrome moly on hand from commercial production. They tried to get permission to use it, but Ordnance kept dithering. When the situation got critical and threatened to halt production, the Works Manager T.I.S. Boak sent this memo to his production head:

“Confirming our conversation this morning, you are to go ahead with the use of chrome molybdenum steel in the production of the hammer, the follower and the catch operating rod for the M1 rifle. I am taking this responsibility on my own shoulders because I fully believe we should not allow a break in production of the M1 even though the Ordnance Department fails to get us steel or give us permission to use steel which we do have.

rifle. I am taking this responsibility on my own shoulders because I fully believe we should not allow a break in production of the M1 even though the Ordnance Department fails to get us steel or give us permission to use steel which we do have.

You are only to make these components of chrome moly steel until the #3115 steel which we have on order arrives. In other words, I don’t want a lot of chrome moly parts made up – simply enough to keep us going so as not to shut down the assembly of M1 rifles.”

-

-

02-04-2011 10:34 AM

# ADS

Friends and Sponsors

-

Legacy Member

I think you miss one of my questions, as welcome as that info is.

The question is "Subcontractors or no Subcontractors, using CM and A, or is it clearly all Winchester internal stamping?

My early Win only has one CM part, the rest A-- so I will not be spending the thousands to answer the question myself as that is what a study would cost if you paid for one and did not just ask a friend to do a simple metal composition "spark test" with a grinder.

Colt Manufacturing--CM, was just down the line. Were they used?

I found Amola Steel brand razor blades from 1939 and Chrysler Amola Steel coil springs, still available on a Google Search.

so Amola is an MFG or a Composition??? and different from CM and WD steel?

As far as asking question, I ask for all the others who would ask or will ask the questions about CM and A.

Forums are in essence info interchange arena's and debating societies as history shows us. They are democratic to a fault and questions can be asked that would normally turn a closed meeting into a perceived insult society. I know no one so that cannot become an issue. It is all for info and what logic may tell us on a path that others have trod before--it is an info superhighway, not a toll road.

Thanks again, but I am still not sure what CM and A are--mfg's or steels of differing compositon from WD steel.

-

-

-

Legacy Member

I see we crossed posts, Great info again!

Now, the bullet guides and trigger housings are ALSO stamped CM early on, as well as clip latches, in addition to the above mentioned hammers and op rod catches. "A" came generally later.

The bullet guides are pretty easily worked and even welded to peen them/raise up the worn down area. That does not sound like chrome Moly, but more like a 1050 spring steel or typical mild steel.

Chrome moly in the thin dimensions can crack easily for the heat treat does not leave a softer center core, like it does in Barrels.

Chrome moly, 4130-4150 was used for Barrels, I assume at both plants, and is listed by Hatcher as so.

The springs in a Garand include the Trigger housing which in essence is a large spring. Many were subsequently modified in the pad area by remachining. Again it sounds more like a milder form of 1050 steel, than heat treated 4150 chrome moly.

include the Trigger housing which in essence is a large spring. Many were subsequently modified in the pad area by remachining. Again it sounds more like a milder form of 1050 steel, than heat treated 4150 chrome moly.

The metallurgy of the Win receiver stayed inthe 3100 series, I believe till the end of production. That steel is not as potentially brittle as the 4150 series of chrome Moly, which was not used for receivers.

Heat treat for the different steels pre production and post production would seem to be a problem as chrome moly in its raw state would need to be anealed to be forged, machined, stamped,--- especially stamped, or cracks would dominate.

Due to the above and your preceeding post, it seems that CM does not necessarily refer to Chrome Moly.

Amola process Steel is historically, a spring steel--likely in the typical 1050 range for spring steel, and is not chrome moly,--far from it and quite different in composition, yet is used for the same parts marked CM.

So the marking of the parts CM or A may not actually refer to the metals used or to ID them, as there seems to be no or little discernable difference upon history/inspection of those marked parts, and little reason to ID them for material.

Also a simple "C", would have sufficed, like A for ID purposes---unless it was Colt Mfg for example.

Historical accuracy is what is in the alpha numeric markings, just like the -1,-2,-3 SA bbl mystery.

Thanks again.

-

-

@redleg:

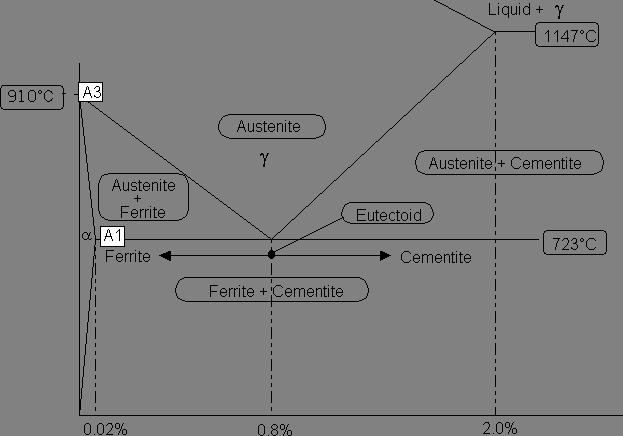

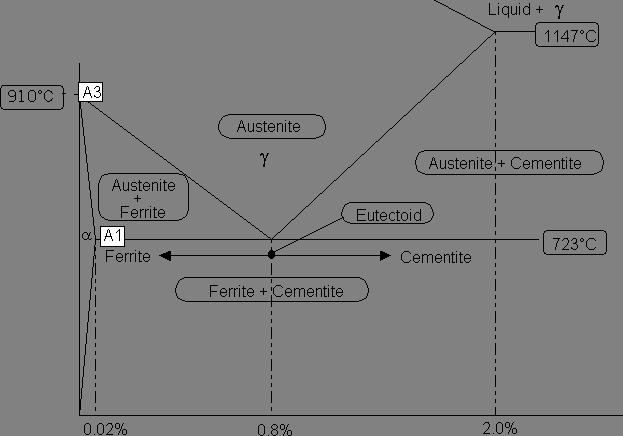

41XX series steels are far more than just 4130 and 4150. Additionally, "heat treat" is a very diverse term. You need to take a look at a phase diagram for steel alloys to see that most carbon steels, even CM, can be made to be almost as soft as low carbon steel, as hard as a file or as tough (hard surface, ductile core) as required - hence why a lot of firearm receivers are made of alloys like 4140.

Here's a basic examples of a phase diagram for carbone steel:

And here is a good read on what this diagram means in more or less layman's terms:

http://www.gowelding.com/met/carbon.htm

A "spark test" won't tell you anything useful. In engineering, a spark test is a specific conductivity test usuallyused to test the efficiency of insulative materials. To determine composition we usually use mass spectrometry if you are destructively testing, or for NDT, we would go to a material composition gun. Both these test aparatus are big dollars though - so you would normally use a lab and pay their fees accordingly.

In any event, your observations about the nature of the parts themselves is not sufficient to change the hypothesis that CM=chromoly.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

The Following 2 Members Say Thank You to Claven2 For This Useful Post:

-

Redleg,

I am not sure what part of Tony Pucci had them tested that you cannot understand? You talk a good game but it does not make the proven facts change. I do not understand the philosophy you are trying to use to argue against fact? It appears that no matter what proof is given, you will refuse to believe.

Please get a hold of the GCA article mentioned before you continue to argue a fact. It really pains me to read how you are treating Bob Thanks,, Rick B

article mentioned before you continue to argue a fact. It really pains me to read how you are treating Bob Thanks,, Rick B

-

The Following 2 Members Say Thank You to Rick B For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

But, but, but,,, wait!!!! It can't be true! It's not in Harrisons book.

-

OK, FWIW, I just went and read the two GCA articles in question and IMHO the debate is OVER. Anyone who would question this data has clearly not read it.

articles in question and IMHO the debate is OVER. Anyone who would question this data has clearly not read it.

Let me summarize the points since I can't re-print the articles in full here without violating copyright law.

1) Bruce Canfield has the wartime correspondence records of Edwin Pugsley, the long-serving General Superintendent of Winchester Repeating Arms Company in his possession and he is using it to write a new book.

2) In the Pugsley material there are a series of written memoranda on WRA stationery clearly indicating WRA received permission for the use of CroMoly and Amola as substitute standards from the Ordnance Department for the purpose of producing non-critical components.

3) Staff from Chrysler, who was providing the Amola alloy, were brought in to help Winchester maste the different heat treatment required for the alternate alloy.

4) The following "non-critical" parts have been made with substitute standard steel: “CM” or “A” marked: Bullet Guide, Clip Latch, Hammer, Follower Rod, Operating Rod Catch, Sight base, Trigger housing, and Follower. “A” marked only: Trigger.

5) The CM and A markings were applied specifically so that the heat treatments would match the material when the machined parts went to the heat treating facilities at Winchester - this because at times all three types of steel were being worked and used for these components at the factory. Ordnance steel was used whenever available in sufficient quantity, but often it was not in great enough supply from 1942 onward.

6) Springfield Armory also used Amola steel. Their Annual Report for Fiscal Year 1942 stated: “An extensive program for the substitution of less critical steels for those now being used in the M1 and M1903 rifles has been and is being undertaken. As a result, several changes have been recommended and it is expected that many more will be. A large number of high alloy components were replaced with steels of the Amola type in test weapons and results are encouraging. The Armory is working with the Winchester Company in an effort to find more readily obtainable steels that are suitable for the M1 rifle components.”

and M1903 rifles has been and is being undertaken. As a result, several changes have been recommended and it is expected that many more will be. A large number of high alloy components were replaced with steels of the Amola type in test weapons and results are encouraging. The Armory is working with the Winchester Company in an effort to find more readily obtainable steels that are suitable for the M1 rifle components.”

7) In 1996 Tony Pucci of Orion 7 had CM parts tested for composition. According to his report: "In April and May of 2006, part samples were submitted to Lehigh Testing Laboratories, Inc. New Castle, Delaware for both nuclear and destructive testing of the parts. [...] The CM-marked part showed positive for Chrome-Molybdenum alloy steel. It is also interesting to note that Winchester changed steel alloys at least four times during their production of [bullet guides]." Subsequently four additional components were submitted to Lehigh for testing. These components were all CM marked and consisted of the following components: rear sight base, aperture, clip latch, and hammer. All tested positive as Chrome-Molybdenum alloy.

I'm not sure what Tony meant by "nuclear" testing, but as he is not a test engineer, I suspect he likely was referring to the samples being run through a mass spectrometer.

In any event, in my opinion as a mechanical engineer and student of history and having actually read the Lehigh composition reports personally, this debate is over.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

The Following 7 Members Say Thank You to Claven2 For This Useful Post:

-

Legacy Member

Thank you!

I am now satisfied about the paper trail;explains a lot. I was not party to that info, as many are not.

As the facts that have been discovered will eventually hopefully end up in books to be published all is good.

The 25 years of GCA issues are likely not available in toto and the eventual pulbication or archieve on boards like this one, will help everyone who does not possess the library, like me.

issues are likely not available in toto and the eventual pulbication or archieve on boards like this one, will help everyone who does not possess the library, like me.

Thanks again.

It was my job to be inquisitive.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Hi All,

First, let me explain this thread bump.

I am a WWII Jeep preservationist. In addition to the vehicles, many of us in the hobby also collect and preserve the on-board toolkit that was issued with each Jeep. Willys and Ford factory documentation is scant. Research and analysis continues, aided somewhat by found NOS partial kits, as well as government manuals (the Ordnance Department assumed responsibility for vehicles and tools from the QMC in late 1942). One of the biggest puzzles remains the double open end engineers' wrenches, specifically, brands (Mfgrs) and markings.

As you can probably guess where this is going by now, these wrenches were made of steel. Alloy Artifacts, a website dedicated to mid-century hand tools, has been a good source of information for us, but the major premise of its wartime dating methodology, which hinges on War Production Board (WPB) controls and composition restrictions on smelting alloys (chromium, molybdenum, and vanadium) and finishes (chrome plating) in late 1941 and early 1942, is vague, and has created A LOT of debate in our community.

That debate, and continued research into the WPB restrictions and the resulting low-alloy "National Emergency" or "War Department" steels, is what led me to this forum and this thread.

WPB records show that the entire chromium supply, including excess stock, was allocated (OPM Order M-18) for defense in July 1941. Molybdenum, including excess stock, was allocated in December 1941, when all alloy steel production was allocated for defense (OPM Order M-21). Effective January 1, 1942, all of the pre-war high-grade alloy steel formulas were disallowed by composition restrictions that capped manganese content at < 1.65%, chromium and molybdenum content at < 0.6%, and restricted vanadium in ANY quantity. That order disallowed the use of Chrome-Molybdenum AISI 41XX. Only the new N.E. or W.D. formulas (AISI 86XX, 87XX) or AISI 13XX or carbon steels (AISI 10XX) were allowed after January 1, 1942. Unless a smelter or a Mfgr had an A-10 or higher preference rating. And that was increased to A-1-K or higher after March 1942.

We have no record of Willys or Ford having those preference ratings for its tools, and some of us assume that common sense dictates that those certificates were likely reserved for airframes, tanks, guns, and munitions, not vehicle toolkit wrenches.

Reading this thread confirms that, since it appears that even a Garand rifle mfgr like WRA had difficulty getting the preference ratings to use chrome-moly for certain parts.

rifle mfgr like WRA had difficulty getting the preference ratings to use chrome-moly for certain parts.

But I do have some timeline questions..

(1) What is the date of the note that WRA Plant Manager T.I.S. Boak wrote to his production chief (per Bob Seijas , post #21)?

, post #21)?

(2) In general, I'm trying to figure out when these alloy steel production changes (references to Amola steel, substitute steel, and "WD8000" steel) hit WRA.

If anyone is interesting in reading more about the OPM/WPB alloy restrictions, we have a long thread dedicated to that subject, with many historical documents posted, here:

G503.com Message Forums View topic - Wartime Alloy Restrictions (click here)

Last edited by Badger; 02-28-2014 at 03:25 PM.

-

Contributing Member

CM Alloys

The Boak memo is dated February 25, 1942. Bear in mind that this chrome/moly was steel Winchester already had on hand from commercial rifle manufacture. Your tools were more likely Amola steel that WRA also used because it was pushed on them as a substitute. Amola was developed by metallurgists at Chrysler and was being touted as something of a wonder metal. It was also a chrome/moly alloy but with different proportions. Chrysler made a lot of car springs out of it, even featured it in some magazine ads.

Real men measure once and cut.

-

rifle. I am taking this responsibility on my own shoulders because I fully believe we should not allow a break in production of the M1 even though the Ordnance Department fails to get us steel or give us permission to use steel which we do have.

PM

PM