-

Banned

-

06-07-2009 01:18 AM

# ADS

Friends and Sponsors

-

Banned

-

-

Legacy Member

I am beginning to think that there are vested interests at work on this thread to keep the focus off the issue of either brass composition used in case manufacture or the manufactureing method used which is causing a problem with head separation in some Lee Enfields.

-

-

Banned

Bindi2

Our American or SAAMI made .303 cases could be made correctly to these standards and the larger chambers of the Enfield could be directly responsible for the short case life. BUT I think other factors could have something to do with the short case life when reloading.

Most of my questions are related to and come from reloading commercial ammunition in my Springfield 03-A3 with its corresponding larger military chamber and headspace and the 30-06 cases lasting far longer than currently made .303 cases.

The problem at Gunboards was my postings concerning cases life, chamber pressures and reloading methods kept getting locked down or the entire post deleted because of arguments from our online internet engineers.

What bothers me the most is the set piece standard answers about the “inherent weak design” or the “action flexing” on the Enfield and the fact no one wants to think outside the box and look at other contributing factors on case life.

And then to add insult to injury when your posts on fire forming cases using o-rings are hijacked by cartridge case oilers, who think they are the only ones in the world who know how to reload, you never get anything accomplished on the subject.

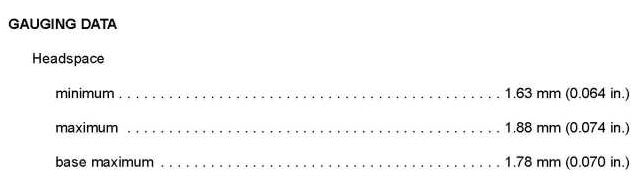

When I look at a 2002 Canadian Enfield manual and see headspace standards that are written for a cartridge case that is to be fired once, which translates to .064 GO, .070 NO-GO and .074 Field I wonder what has changed and why.

Enfield manual and see headspace standards that are written for a cartridge case that is to be fired once, which translates to .064 GO, .070 NO-GO and .074 Field I wonder what has changed and why.

(I keep thinking it might be the brass case and the standards used to make them)

Last edited by Edward Horton; 06-07-2009 at 12:03 PM.

-

Legacy Member

#4 MK1 Lee Enfield bolt and receiver deflections at a given PSI

These are real numbers.

These numbers can be duplicated in Excel if you are interested.

The formulas and techniques are readily available on the internet.

All dimensions are in inches, pressure in PSI.

Note the deflections translate into stretching of the pressure ring

when the case body adheres to the chamber wall and the case

head is pushed against the bolt face.

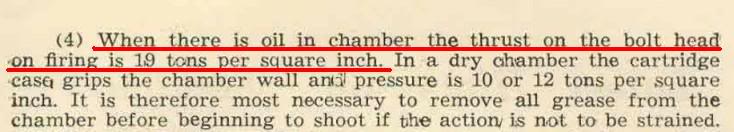

I personally think it is poor practice to use case head stretch as a mechanical brake to minimize load on the action. Everyone that cleans a gun usually fires a shot or two with oil in the chamber each time they go to the range.

.......................Receiver.......Bolt........ .Total Deflection***

...PSI............... Stretch....Compression Receiver+Bolt

30000................0.0009.......0.0037.......0.0 046

35000................0.0011.......0.0043.......0.0 054

40000................0.0013.......0.0049.......0.0 062

41440................0.0013.......0.0051.......0.0 064

45000................0.0014.......0.0055.......0.0 069

50000................0.0016.......0.0061.......0.0 077

55000................0.0017.......0.0068.......0.0 085

60000................0.0019.......0.0074.......0.0 093

65000................0.0020.......0.0080.......0.0 100

70000................0.0022.......0.0086.......0.0 108

75000................0.0024.......0.0092.......0.0 116

80000................0.0025.......0.0098.......0.0 124

85000................0.0027.......0.0104.......0.0 131

90000................0.0028.......0.0111.......0.0 139

95000................0.0030.......0.0117.......0.0 147

Last edited by ireload2; 06-07-2009 at 05:18 PM.

-

-

Legacy Member

Originally Posted by

Bindi2

The Lee enfield requires a certain amount of friction grip between the case and chamber to reduce bolt thurst, oiled cases where used to limit the friction to check to see if the lugs were correctly where they should be before the Goverment inspector passed the rifle for Goverment ownership.

British

Goverment requirement. Machine guns do not require that friction many will not operate with sticky cases hence oil on cases.

Do you have citations for your assertions?

What is the certain friction grip? Is it quantified? What happens if you clean your and oil you gun with PTFE lubes?

This friction grip is modified by polishing your brass. It can also be modified by polishing your chamber. Are you also implying that you should not polish your brass or the chamber?

All rifles inevitably get fired with some oil in the chamber.

Are you saying this will damage a Lee-Enfield?

Is that why Lee-Enfields seem to have such gross headspace?

Do you have answers for any of this?

-

-

Legacy Member

Posted by EH

>>>Springfield 03-A3 with its corresponding larger military chamber and headspace and the 30-06 cases lasting far longer than currently made .303 cases.<<<

You can easily measure the Springfield receiver and bolt that permit you to calculate the stretch of the receiver and the compression of the bolt.

If you will do this once for the Lee-Enfield and once for a front locking bolt gun you will have a lrge part of your answer. There is no magic.

-

-

Legacy Member

Posted by Parashooter.

>>>I believe those who assert that radial expansion contributes to the kind of head separation commonly encountered by .303 reloaders are mistaken. Radial expansion puts the circumference of the solid case web in shear, not stretch - and it does so in a completely different location.<<<<

The case pressure ring material has to stretch radially until it it constrained by the chamber. There is some bending since the stretch occurs at an angle due to the proximity of the solid head. However this still results in the pressure ring being stretched buy the difference in diameter of the case and the chamber as well as the forces that stretch the case along it's longitudinal axis. Stretch along the relatively long longitudinal axis has the opportunity to get spread over a long portion of the case length. The radial stretch that occurs to the pressure ring area is concentrated over a short distance increasing it's damage to the case wall. If there was no stretching caused by the difference in diameters it would be possible to use a much smaller cases head with no consequences. We know that is not possible.

-

-

Legacy Member

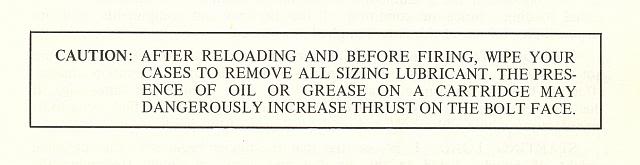

[QUOTE=Edward Horton;54858]Sometimes I wonder what people are thinking when they decide to cheat and bend the rules on gun design and cause possible gun damage and accelerate wear on a rifle designed to shoot ammunition that is not lubricated..

The Enfield Rifle has already been labeled “an inherent weak design” and an action that flexes due to its rear locking lugs, WHY on earth would anyone want to lubricate a cartridge case in the Lee Enfield rifle and cause TWICE the force to be delivered to the bolt face and twice the damage and wear this rifle was designed to receive is beyond me.

has already been labeled “an inherent weak design” and an action that flexes due to its rear locking lugs, WHY on earth would anyone want to lubricate a cartridge case in the Lee Enfield rifle and cause TWICE the force to be delivered to the bolt face and twice the damage and wear this rifle was designed to receive is beyond me.

I spent the last 25 years of my career as an Inspector at a military overhaul depot and it never fails to amaze me how many people ignore warnings and instructions in the manuals because they “think” they are “smarter” or “know more” than what is printed in the manuals.

97% of all errors are human errors and only 3% are actual mechanical failures and egos and assumption are the major cause of mechanical breakdowns and component failures and this is what causes aircraft to fall out of the sky.<<<

Interesting to think that an inspector thinks he knows more about the rules than the engineers that make them.

All errors are human errors. BTW manuals are full of errors. Even inspectors have an error rate. The only way to stop errors is to kill all the people.

You lubricate the case so you don't use the case as a mechanical brake.

Using the case as a mechanical brake guarantees damage to the case. To avoid damage to the action reduce the loads. You can't stop it from flexing.

-

-

Advisory Panel

Dear All, let's keep calm.

I am getting worried. I am trying to learn something from other people who have knowledge that I do not possess, but have the increasing feeling that merely asking why or how is sufficient to cause offense. If that is the case, then the forum will not function in the sense of a profitable exchange of ideas and information.

I am grateful to be able to read contributions that provide facts and experience that I do not have and cannot otherwise acquire. I was a development engineer and then head of a development laboratory in a very large international company for many years. An activity that requires that you know the book, before you start, but also that you are prepared to investigate some of the assumptions in the book, without that being considered frivolous or those who wrote the book becoming offended. I would like to see the forum progress in this spirit

In the case of the rear-locking bolt construction of the Enfield, I am charmed by the brilliant simplicity of the O-ring method, and will try it out when the competition season has tapered off.

But a thought occurs - assuming that ireload2 has used the correct modulus of elasticity etc, then we are faced with the following limitation: even if we have an Enfield action with a zero headspace, then, if the case head remains in contact with the bolt head, the case head will be pushed back as the bolt is compressed, and then pushed forward as the pressure drops. So a case that has been held up against the bolt face with an O-ring will, after firing, have undergone a rapid cycle of stretching and compression by the amount of the bolt compression, even if all other play is zero.

In other words, the rear locking bolt system is going to strain the case even if there is a perfect case-chamber match. And the only way to reduce that effect is to reduce the pressure peak. So while I am sure that the O-ring method is a very good idea to reduce the cartridge strain, and should therefore increase case life, there will still be a strain cycle that will, eventually, cause the cartridge to fail. It would therefore be interesting to hear if there is any data on 303 cartridge life using the O-ring method.

Patrick

-

semi-automatic rifle in limited use by the Swedish Army from 1942 until the 1960s.

MAS-49 and American M16

rifles. The Ag m/42 also uses a tilting breech block like the Tokarev SVT-38 / SVT-40 and FN FAL rifles.

Lee-Enfield and Soviet

SVT-40, the Ag m/42's magazine was intended to be removed only for cleaning.

Register To Reply

Register To Reply