-

Contributing Member

-

Thank You to desperatedan For This Useful Post:

-

09-12-2015 07:40 AM

# ADS

Friends and Sponsors

-

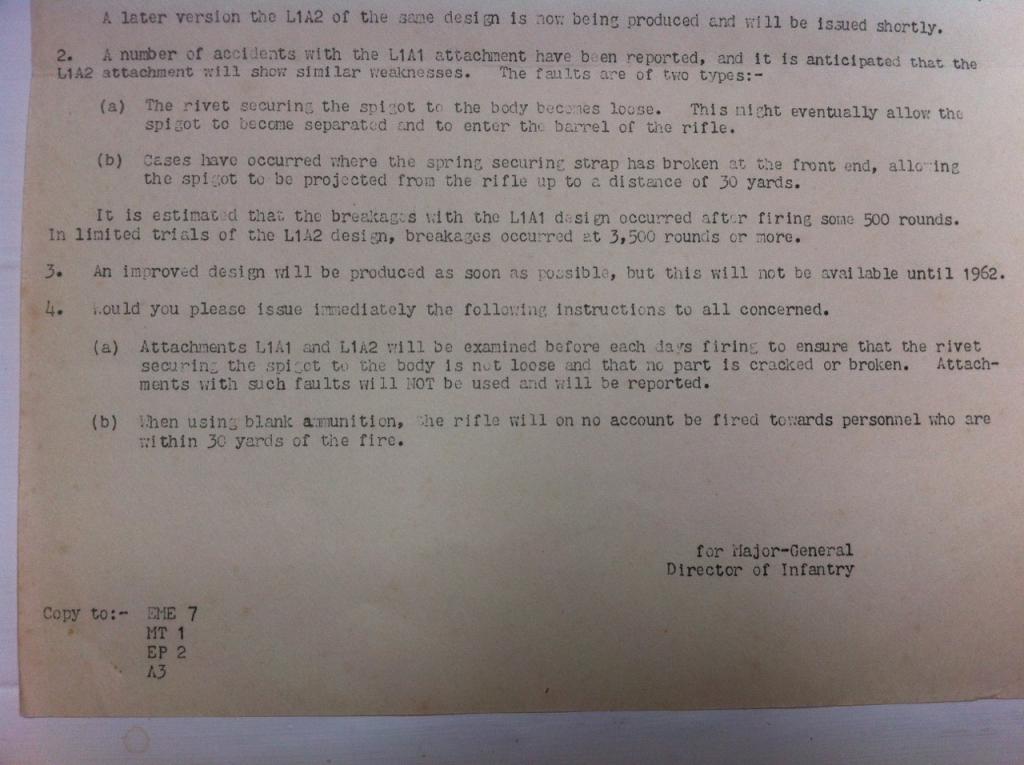

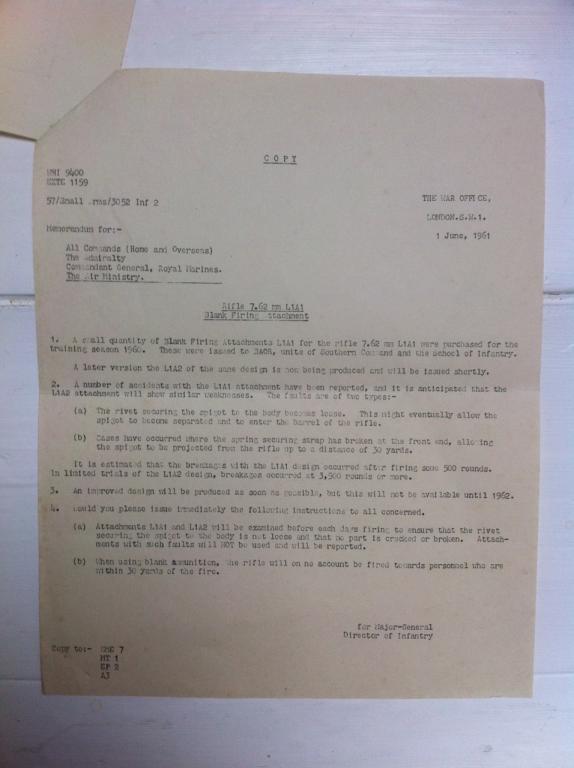

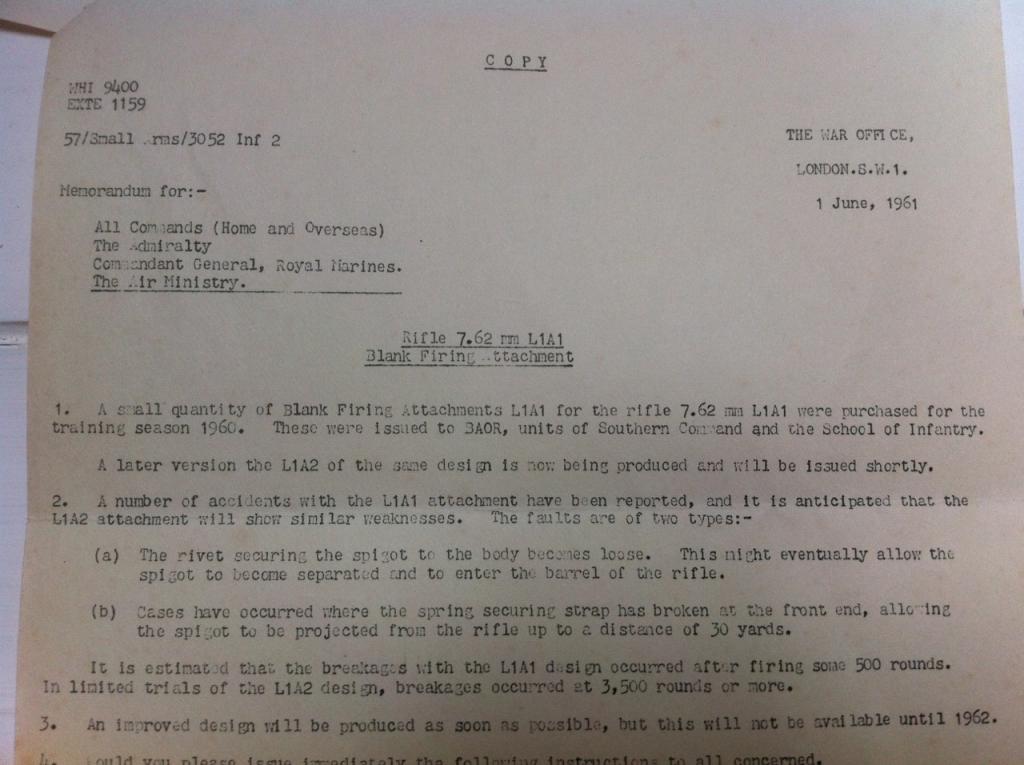

The 'choke', the stainless steel bit that goes into the muzzle was 'roll' rivetted radially which made it more secure. Thinking on my feet here, but...... I'm not sure that if the detached choke (para 2a above) fell into the barrel it'd be dangerous as such because if you did fire a blank after wards, it'd just fire the choke up into the remains of the still attached BFA.

Added later: Just read the old EMER and the choke of the A2 version was roll rivetted over a larger dia washer too to presumably give it more strength

The bit at the front they talk about (para 2b above) would fracture due to it being subject to extremes of instant heat/cold/heat cold. As it fatigued it fractured. The rear end was attached to the bayonet standard while the fractured/detached front end went whizzzzzing off down range........

Someone remind me.... Didn't the early type have a longitudinal recess in the spring loaded part of the strap while the later one didn't have the recess making it stronger but still prone to fatigue and recognisable from the earlier version. Memory is failing.

The problems - if they were ever REAL problems that is - were never really resolved until the overly complicated last design came on stream due to the advent of ar5e covering and health and safety. Think SA80 BFA's and magazines..........

There's probably more to it than that of course but certainly, fractures of the spring steel retainer was a problem.

Last edited by Peter Laidler; 09-12-2015 at 11:25 AM.

Reason: add a bit and korrekt sum speeling misteaks

-

The Following 3 Members Say Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

-

The Following 3 Members Say Thank You to nzl1a1collector For This Useful Post:

-

Legacy Member

-

The Following 4 Members Say Thank You to nzl1a1collector For This Useful Post:

-

I only remember the ones that were clamped on (pics 4 and 5) plus the big head banger type (pic 6) but the rivetting and large rivet are clear. You can see the 'U' bend where the spring part would crack across and eventually break* There was a special tool for reinforcing/re-rivetting the L1 type. I seem to think that they were made by a small sub-contracting firm called JETAGE or JET-AGE in West Bromwich who made lots of small parts.

These cheap pressed steel BFA's were a bone of contention when the big workshops were privatised to ABRO. They would be sent in to be acid dipped to clear the carbon, stripped phosphated and repainted with high oven bake paint. But because everything was costed on a commercial basis. But due to the quantities being done, especially at the large training centres, the actual cost per unit was absorbed into a average cost per, say 10. That is where 5 would need a new choke tube, 6 would need new clamp springs, 5 would need new sliders..... You know the sort of thing.

You would come out with an aggregate cost of repair. THAT cost exceeded the cost price paid by Ordnance!!!!!!!!!! As a result it was uneconomic to repair/rebuild or even repaint them at any level past the unit level. So they were used and cleaned repeatedly until they went black and were replaced with new.

Some units would clean and respray with shake cans to prolong their life but that was really just a one trip quick fix. Different with the big head banger ones though

*were these breaking a problem with you Tankie and Skippy? Not a particular prob in the 60/70's to me. Never saw it highlighted as suck. Just working loose which was a fairly simple tighten up job every so often

-

-

Advisory Panel

The C1 BFA, if it's meant to be the Canadian one is broken. Ours were the same as the L1A1 BFA. The spring is missing and it is in danger of flying off. Also we painted our yellow, same as the L1A1. The one you show has been stripped of paint and would be classed as unserviceable.

one is broken. Ours were the same as the L1A1 BFA. The spring is missing and it is in danger of flying off. Also we painted our yellow, same as the L1A1. The one you show has been stripped of paint and would be classed as unserviceable.

-

-

Legacy Member

Never experienced a Fractured one Pete. But have seen a couple of cracked ones.

Not suprising when you think of amount of 'traffic' they might handle!.....

Moded THOUSANDS of the blighters, from removing the wingnuts. & fitting flat section coil springs,washers, & rivitting the shank head of the screw over to retain it all.....

-

Thank You to tankhunter For This Useful Post:

-

Advisory Panel

We had damages at the front bottom of the outside spring attachment where it would break and the inside spring would retain it. I took that spring off a couple times and tried it without and found it was required... Never saw a spigot come off completely. Even if it did, I think you'll find it's too big to go inside the bore. It's designed to PLUG the end of the bore and just fit in the F/E. We also found that using a hose clamp to retain our would almost guarantee the broken BFA. I always thought it was because of lack of flexibility when it was firing.

-

Thank You to browningautorifle For This Useful Post:

-

Legacy Member

The C1 BFA, if it's meant to be the

Canadian

one is broken. Ours were the same as the L1A1 BFA. The spring is missing and it is in danger of flying off. Also we painted our yellow, same as the L1A1. The one you show has been stripped of paint and would be classed as unserviceable.

The C1 BFA was the first BFA to be developed and issued, but didn't last long because it would fly off so the extra sliding locking spring was added creating the C1A1, or in British service the L1A1 BFA. The C1 BFA's were withdrawn from service.

service the L1A1 BFA. The C1 BFA's were withdrawn from service.

-

-

Advisory Panel

That makes perfect sense. That would have been back in '56-'58...? Looks like they took the idea originally from the M14 BFA.

BFA.

-

Information

Information

PM

PM