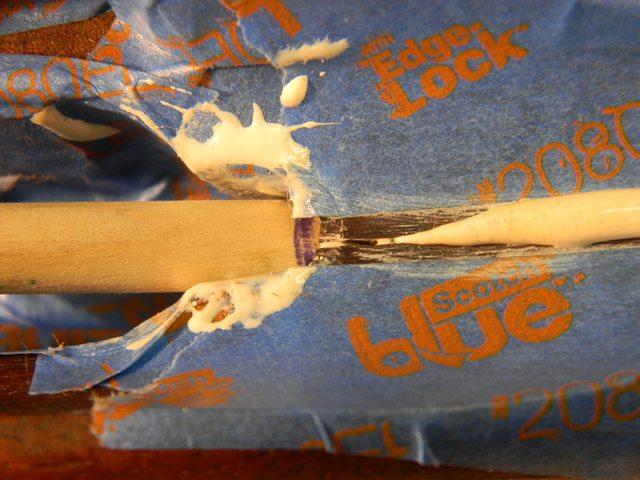

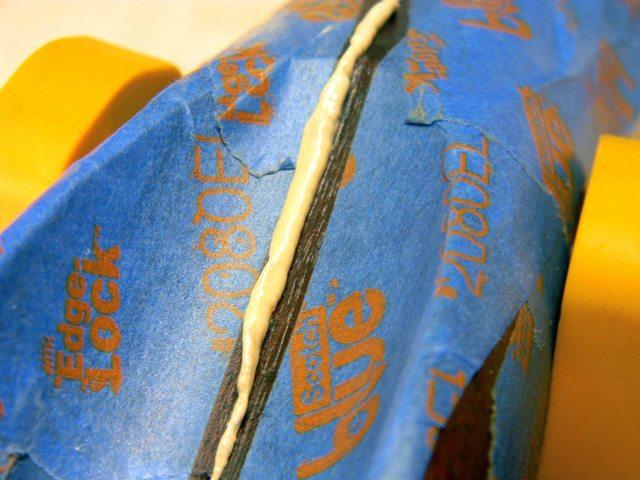

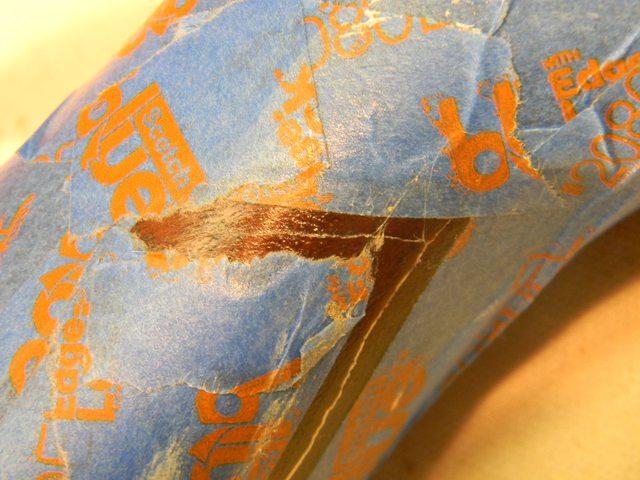

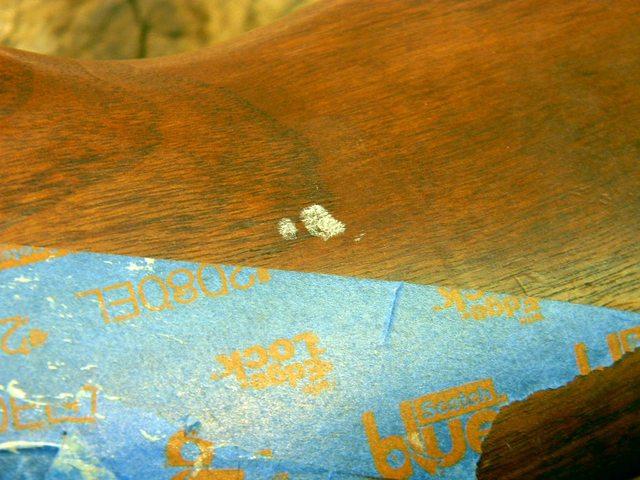

On occasion I have injected glue into a crack by drilling a !/4 inch hole into the joint. The hole is completely filled with glue and a 1/4 inch dowel is pushed or tapped in after. The glue is under hydraulic pressure and will completly fill the joint. Let it squeeze out on all sides to be sure it is filled. Clamp and wipe off the excess. The hole can usually be drilled from a hidden starting point, say like the butt end of the stock which will be covered by the buttplate. I have also done this on a few stocks cracked just behind the rear tang screw. The hole is started in the pocket for the rear tang (won't be seen after assembly) and runs the depth of the crack. Some through cross bolts ( llike on a 1903 Springfield) will prevent a new crack. This may not be applicable in Cantgrowup's carbine project but it does work when a crack won't spread far enough to get the glue in. Works great Salt FlatInformation

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM