-

Legacy Member

M1A1 Stock Common Crack Theory

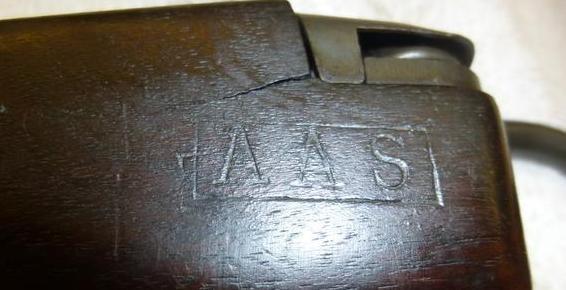

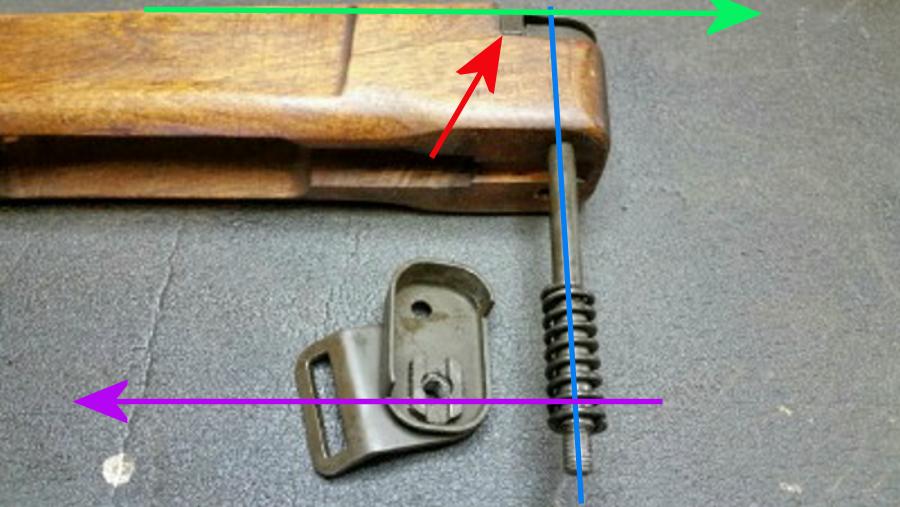

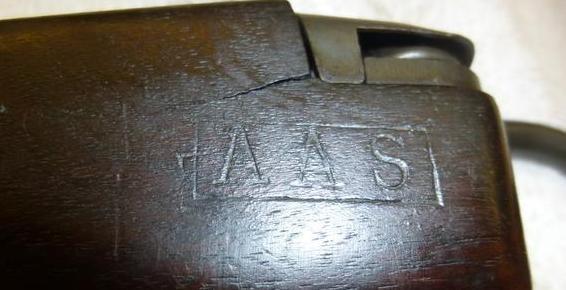

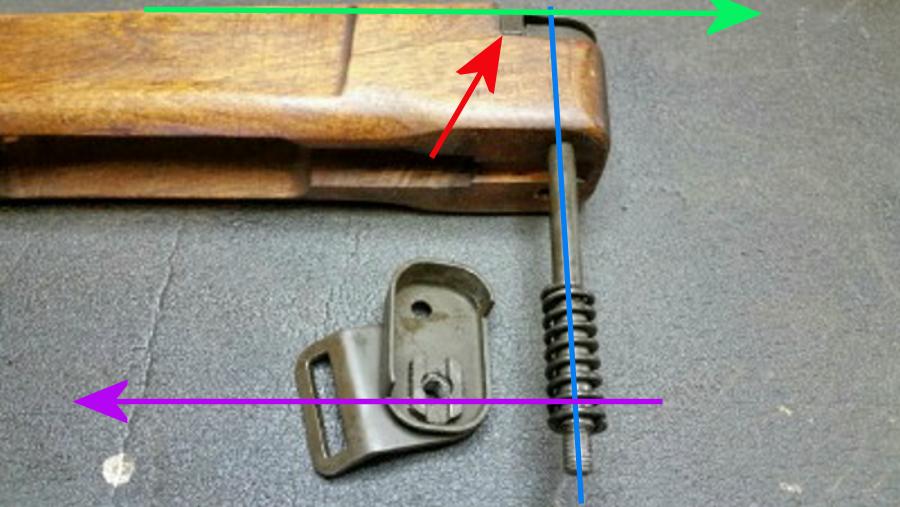

I am fixing the crack in this stock for a member. I was also asked from some members why this is common and is it a fault of the design. I do not believe that it is a fault. I believe that it occurs from the forced removal of the wire portion of the stock. The long bolt with the spring goes through a close fitting collar then into the lower sling swivel that cups on the bottom of the grip. The bolt can seize the collar if it is not lubricated. If someone tries to hit it out, is when I believe the stock cracks. These stocks are very valuable so please keep them lubed and use plenty of caution if you have to take them apart. This particular stock is natural low wood that went through a rebuild at Rock Island sometime between 1947 & 1958. That is when it probably received its MWO ORD B28-W2 modification.

Best Regards.....Frank

Attachment 74928Attachment 74929Attachment 74927Attachment 74931Attachment 74932Attachment 74930

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

The Following 4 Members Say Thank You to frankderrico For This Useful Post:

-

08-04-2016 02:46 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

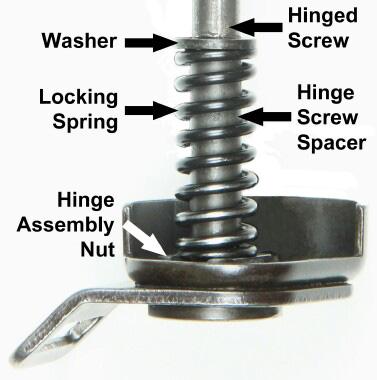

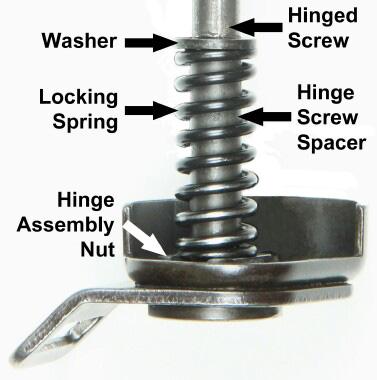

Is the washer that sits on top of the hinge screw spacer to compress the spring missing or was it eliminated during the rebuild?

Looking forward to the details and process on the fix. <0

-

FREE MEMBER

NO Posting or PM's Allowed

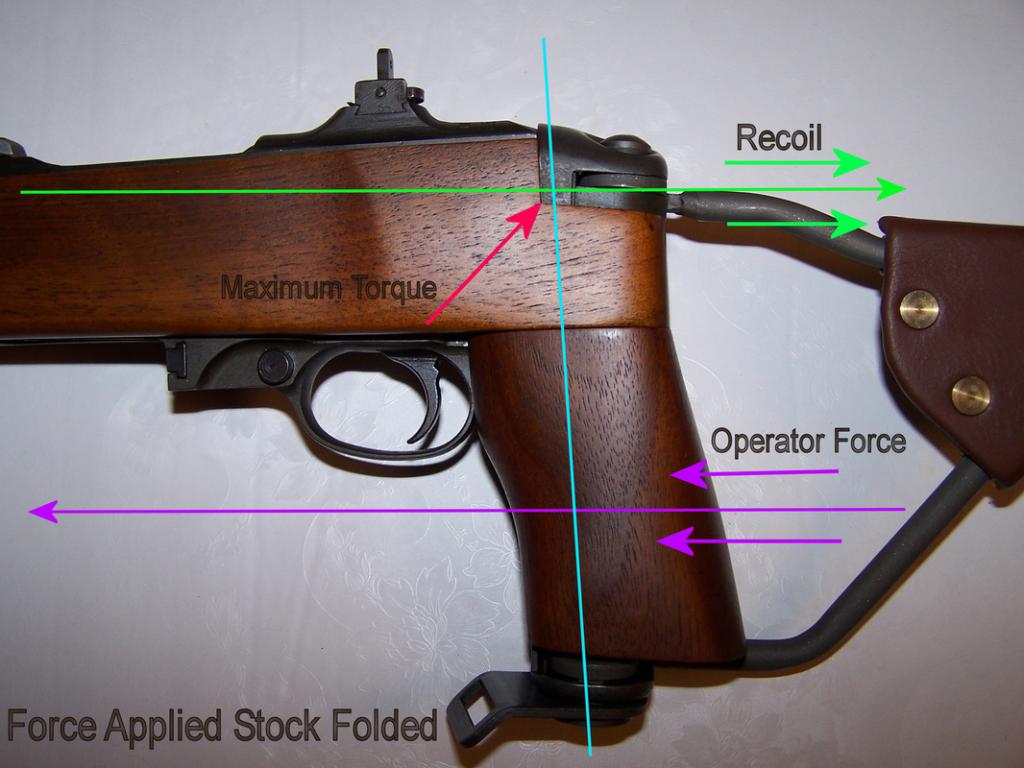

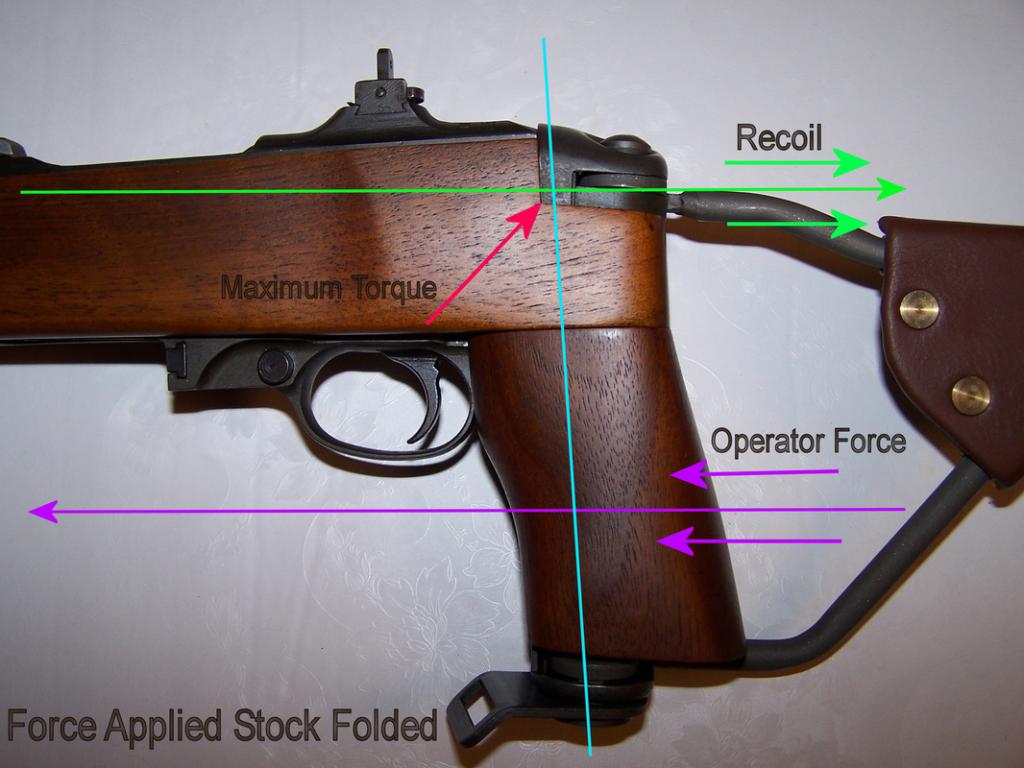

While browsing for sale items I noticed this phenom a few times already. If it's not caused from overextending the stock, something else, perhaps the nonlinear arrangement of the grip and forestock is cracking it from the recoil. Deployed the wire stock is not centered at the back but is to the right side. Torque at the opposite corner?

-

Legacy Member

Could it be caused by a lot of shooting with stock folded?

The hand grip takes all the recoil.

M1a1's-R-FUN!!!!!!!!!!!!!!!!!!!!!!!!

TSMG's-R-MORE FUN!!!!!!!!!!!!!

ENJOY LIFE AND HAVE FUN!!!

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

shadycon

Could it be caused by a lot of shooting with stock folded?

The hand grip takes all the recoil.

Makes sense. That is a lot of force transmitted to the grip, resulting in a big jolt of torque to the forestock right at the front edge of the recoil plate. The recoil plate keeps the last inch or so of the forestock contained and stable but when fired the inertia of the action/barrel pits rearward forces against forward forces, trying to jackknife the gun at the recoil plate. The wood on the left side at that area must be thinner or weaker and cracks. Even worse chance if the grip screw is loose, one reason they switched to the longer ones I think.

I'm not sure but I suspect since this mod of the M1 was a rushed item, they may not have anticipated it being fired routinely with stock folded and didn't test the design thoroughly for that case. Wasn't it a space and weight consideration? Almost impossible to aim through a peep sight without a stock to stabilize the gun so surely they didn't expect widespread use without the stock deployed?

was a rushed item, they may not have anticipated it being fired routinely with stock folded and didn't test the design thoroughly for that case. Wasn't it a space and weight consideration? Almost impossible to aim through a peep sight without a stock to stabilize the gun so surely they didn't expect widespread use without the stock deployed?

Over flexing the stock in the open position could also be a cause but unless someone is willing to destructively test I don't think we will find out. Of course an old solder or ordinance expert might have seen it or heard firsthand how it happened.

I think Shady may have nailed though. Knowing how these go together now I think even a few shots stock folded could crack them at that corner.

Last edited by HDSledge; 08-07-2016 at 04:48 PM.

-

FREE MEMBER

NO Posting or PM's Allowed

Noticed something interesting in Frank's pic. I can see how the long hinge screw is on the side that cracks and probably contributes most of the torque. Could be why the left side is cracking and not the right.

Also on the right the recoil plate is firmly held down by a screw. On the left side the recoil plate is not held as firmly to the wood by the hinge screw. It slides through the cap, recoil plate, and grip and screws into the nut on the bottom of the grip.

I imagine if you held the forestock in your hand, took a hammer and hit the hinge screw in the direction of the purple line, the stock would crack right at the corner. The more I look at it the more I think Shady is on target. Mystery solved?

-

firstflabn

Guest

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

firstflabn

Moment, not torque.

You got me on that one.: The definition of torque states that one or both of the angular velocity or the moment of inertia of an object are changing. And moment is the general term used for the tendency of one or more applied forces to rotate an object about an axis, but not necessarily to change the angular momentum of the object

But wait: A moment of a force is the same thing as a torque.

I unsurrender.

Last edited by HDSledge; 08-07-2016 at 10:02 PM.

-

Advisory Panel

With a square corner there odds are it will crack, no matter whether it's force or abuse. That's the reason they changed the corner to a circle cut on the M1 rifle op rod. This is the same. A square corner cracks.

rifle op rod. This is the same. A square corner cracks.

-

The Following 3 Members Say Thank You to browningautorifle For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Last edited by HDSledge; 08-08-2016 at 11:43 AM.

PM

PM