Ireload,

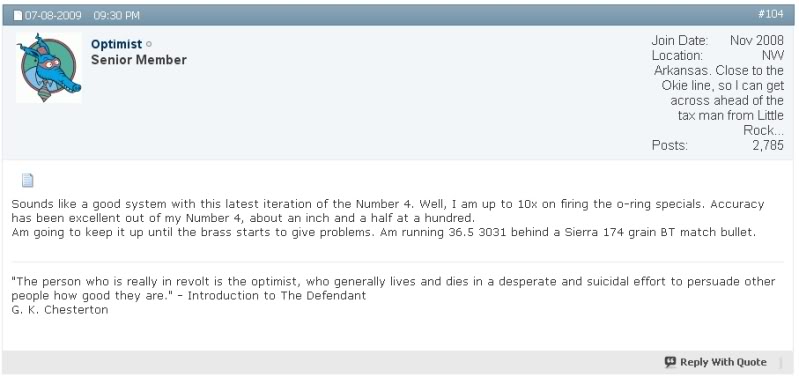

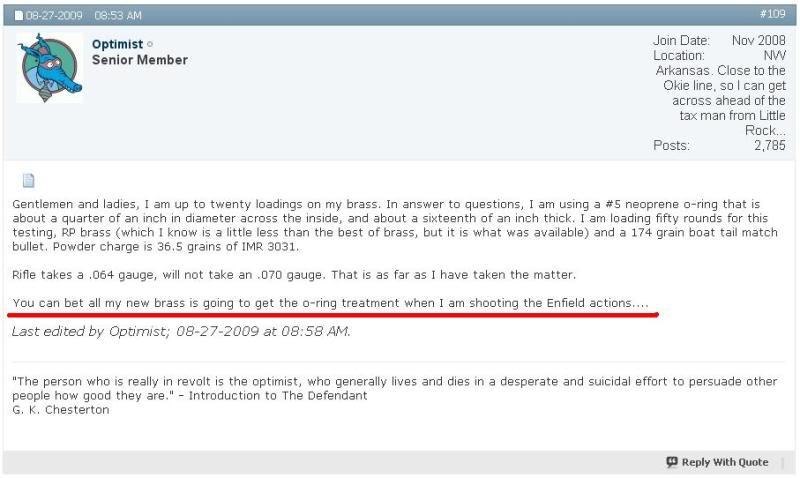

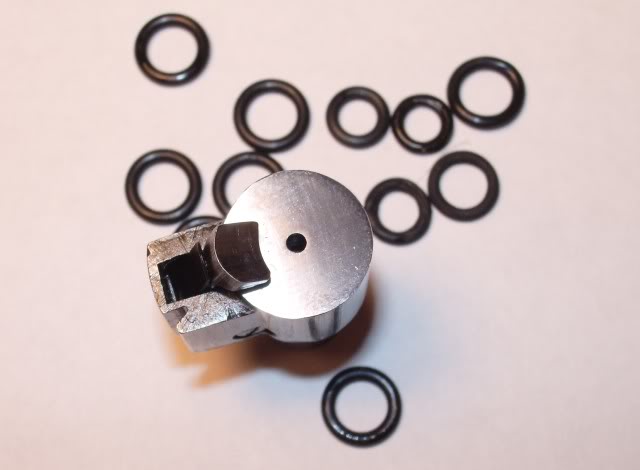

The point about stretching and subsequent separation is that it always takes place about 8 mm in from the case head. That shoulder is not weher teh case splits, strangely, and this is why: As the case expands during firing, it adheres to the chamber where it is thin (at the neck, then shoulder) and the thick part is pushed back. This thins out the case. The little O ring serves to press the case head snug against the bolt face before firing, so that it is already as far back as it can be when the expansion-adherence-stretching takes place.Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM