-

Legacy Member

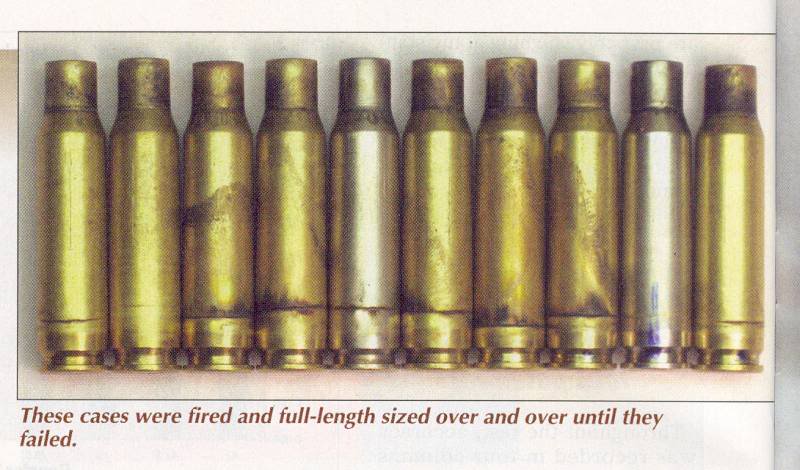

looking at the picture above - the two cartridges on teh right have a shiny area above the head, more noticeable on teh right hand case. Is this where the case has stretched and is this super bad? I've noticed this on alot of my cases.

-

-

09-08-2010 04:31 PM

# ADS

Friends and Sponsors

-

Banned

-

-

Contributing Member

I agree you should segregate cases for each rifle and neck size. I have had no more case separations since I adopted this method; when I was full length resizing I had plenty of separations, even on 1st reload. Sellier and Bellot cases are awful for separations - Prvi Partisan are good cases.

If you have orphan cases, neck size them and then try them in your rifles to see which they will fit.

I use 174 grain FMJ boat tails (the cheapest supplier is the Flying Dutchman, he visits Bisley fairs a couple of times a year, see his website http://www.bold-action.com ) and 40 grains of Vihtavuori N140

-

-

Originally Posted by

newcastle

looking at the picture above - the two cartridges on teh right have a shiny area above the head, more noticeable on teh right hand case. Is this where the case has stretched and is this super bad? I've noticed this on alot of my cases.

If they're only once fired that isn't going to be a problem.Often they look a bit like that, the shiny ring that occurs before separation is not the same as the shiny band just in front of the rim, where the case begins to taper often looks a little suspect, but usually it's fine. Just do some and you'll pick up the little details as you go.

I've had 2 case separations ever in .303 reloads, and they were almost consecutive in a batch that had been reloaded about 20 times, it's not a big deal, and you'll learn how to spot it most of the time.

-

-

Banned

-

Legacy Member

Thanks for all your advice. Now all I have to do is find time to deprime 4000+ cases, get the wife out of the house to use the dishwasher, have time to dry them all outside in the sun and get reloading.

-

Thank You to newcastle For This Useful Post:

-

Legacy Member

>>>In the bottom photo is a new American Remington case and it is setting over a 1/4 inch below the lip of the gauge. This means the shoulder of the case is a 1/4 of an inch shorter than standard British military ammunition.<<<

military ammunition.<<<

From the photo 1/4" is a bit of exaggeration. In any case (to make a terrible pun) I don't an O ring the size of a B-36 tire will correct it.

-

-

Contributing Member

Ireload,

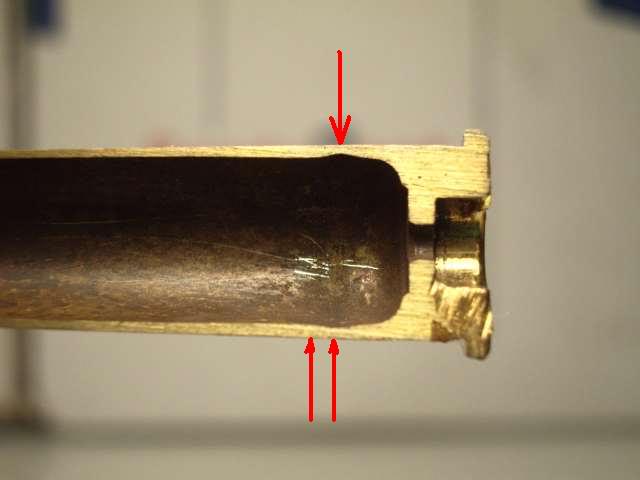

The point about stretching and subsequent separation is that it always takes place about 8 mm in from the case head. That shoulder is not weher teh case splits, strangely, and this is why: As the case expands during firing, it adheres to the chamber where it is thin (at the neck, then shoulder) and the thick part is pushed back. This thins out the case. The little O ring serves to press the case head snug against the bolt face before firing, so that it is already as far back as it can be when the expansion-adherence-stretching takes place.

-

-

Legacy Member

Originally Posted by

RobD

The little O ring serves to press the case head snug against the bolt face before firing, so that it is already as far back as it can be when the expansion-adherence-stretching takes place.

I tried the O ring method a few weeks ago for the first time. Five shots, 5 O rings split in two down the middle leaving me with 10 thinner O rings. The brass looked only slightly better than without the O ring.

-

-

Legacy Member

RobD,

So tell that to the guy claiming the location of the shoulder is the problem. You have missed several thousand posts about the same subject.

-

PM

PM