Was this the one ? (an old Jousterposting)

CHS - Body and bolt wear

Posted By: Peter Laidler

Date: Mon 28 Apr 2008 9:17 am

You should all read and re-read this if you have ever thought about CHS, body wear or fitting a new bolt, especially in response to the recent thread about the matter.

I was having a chat to one of the most senior examining Armourers at a huge Base Workshops at Warminster a few days ago. Long retired, he was a 1930's apprentice and one of the very strict examiners. I was asking him about chroming bolt heads to get longer life out of heads bolts and bodies when he reported back something that was VERY interesting.

He said that during the mid 50's, there was a plan mooted to make a No4 size bolt head available so as to decrease the number of old wartime/tired/just plain worn out rifles being condemned as unfit simply because of insufficient CHS. The alternative was to increase the MAX CHS to .078".

He was involved in this project as the research Officer, so was in from the start. The PROBLEM was that once the BOLT, Inspectors, Gauge (a calibrated slave bolt used to test wear) plus a calibrated No2 bolt head (No3 not permitted at Base/Factory don't forget) had been inserted into the inspectors gauge bolt, then making a further bolt head available was palliative and not a cure because these simple tests indicated that it was the BODY that was worn and not the bolt or the face of the barrel. And thinking about it, while it's obvious really, it's absolutely correct!

Another problem they encountered was that with the speed of wartime production, the induction hardening of the bodies was at best, mediocre, and at worst, sometimes virtually non existant. The hardening sometimes had no depth and it was tested at Base Workshops by the old IZOD impact test method. Apparently, all manufacturers were as bad or good as each other including Savage and LB (I bet that has shocked a few of you who were probably lead to believe that some makers were 'better' than others......)

I spoke about resurfacing bolts but he just shook his head sternly and wagged his finger as if to say. 'No, it's the BODY that's worn beyond the point of no return and once the hardness is gone, then there is no cure.'

There, that's straight from the horses mouth and it doesn't come any clearer or louder than that. If you cannot get CHS with BOTH bolt lugs bearing evenly using a No3 bolt head, THEN trying a new bolt, then it is the BODY that is finished. Sorry about that.....................

CHS and boltheads.... further

Posted By: Peter Laidler

Date: Tues 29 Apr 2008 1:13 pm

In Response To: Re: Peter : No3 Boltheads (peter laidler)

In response to KimW's note. And it's this. Maybe I shopuld have included this in the last thread about worn bodies....

For all of you that want a 'tight' headspace on your No4 or 5 or 'T', by making sure the bolt JUST closes down on the 'GO' gauge using the tightest bolthead. Remember this. You aren't making the cartridge seat tighter in the chamber, all you are doing is crushing the rim tighter between the barrel and the bolt face. This is the reason why all (?) the .303" weapons were .064 GO and .074 NO-GO.

On the RIMLESS 7.62mm versions it DOES make a difference because the bolt face is closing down in the gauge or cartridge case that is seated about a point on the neck of the cartridge case. This is the reason why different 7.62mm rimless rifles all have different CHS, such as 1.6325 go and 1.643 NO GO for the L1A1 and yet another set for the Bren and 1.628 GO and 1.635 NO GO for the L42 and so on.

There's a bit more to it than that of course but that is the basics. The lesson, as I was always taught it is 'DON'T OVER CHS'. It's not needed and a waste of time so long as uit's within the gauge limits. Seems fair enough to me.............

---------- Post added at 07:28 PM ---------- Previous post was at 07:21 PM ----------

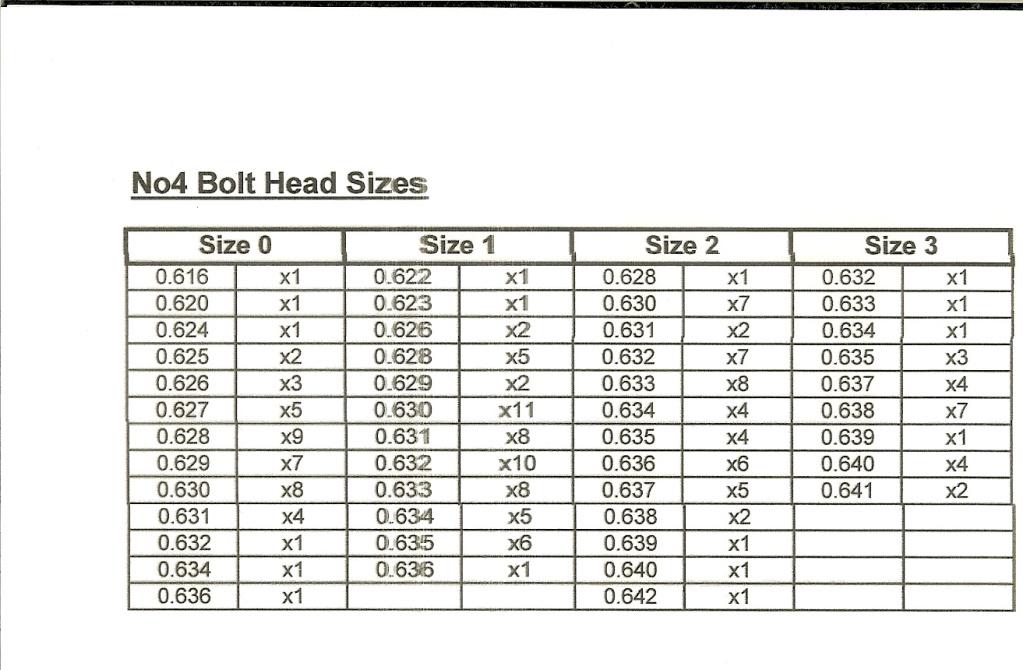

This was a table of bolt head sizes I produced 2 or 4 years ago - I've kept it going and now have over 200 examples (but this is the original version)

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM