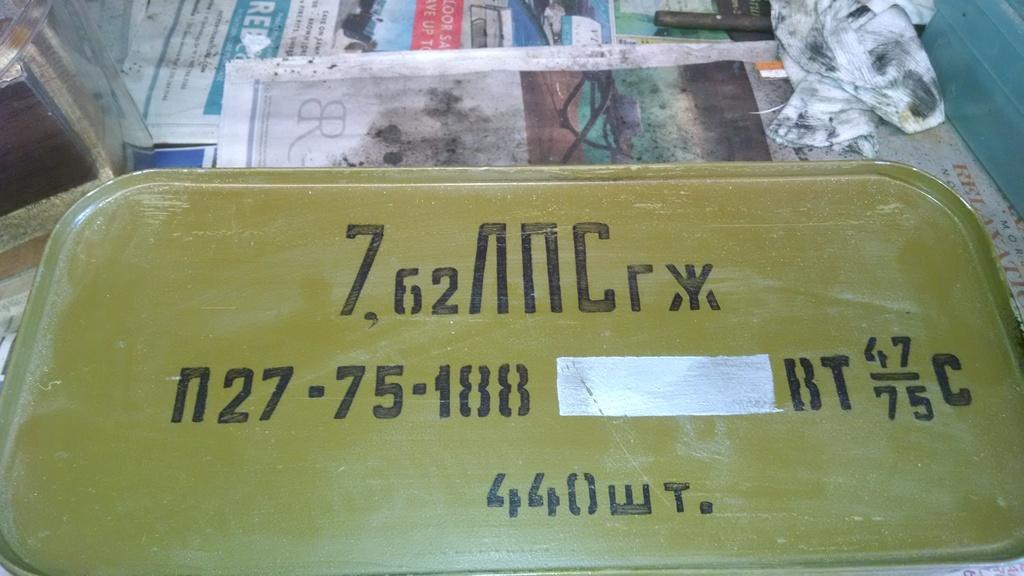

OK so now the "explosive update" I got the rifle back from Troy who very kindly agreed to re-ream the barrel for me. I used a DIFFERENT spam can of 54R. (see pic) Fired 60 round FLAWLESSLY (no case fatigue at all) then.... on the first round of a fresh mag. BOOM!!!! The case failed on BOTH sides (see pic) and blew the mag out of the rifle!!!!. The Builder claims it's and "ammo issue" and won't help. (of course he build the damn thing with the express purpose of shooting Russiansteel cased surplus ammo....but that's another issue).

So.... gang, I'm on my own with this thing. Need ideas. How does the rifle cycle 60 times perfectly and then have a catastrophic failure like this! Again, seems clear that the cartridge is unsupported in two places where the barrel is beveled in the back so... does head spacing matter when the casing is unsupported on the sides no matter how close the rim of the case sits? Keep in mind that when he first sent the rifle to me the first barrel caused every cartridge to blow out, but for whatever reason, the gas pressure was never enough to blow up the mag. When I got it back, the new barrel (or combination of barrel and rifle) now causes a BOOM ever 60 rounds or so.

At least he seems to have fixed the recoil spring issue. I cycles fine, but does have the LITTLE problem. We need to resolve. Can't expect any casing to withstand the pressure without the support of the barren or other mechanism.

Thanks for the help. I'm on my own and don't build guns myself so....... All help/ideas are welcomed.

SEE PICS BELOW

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM