-

Contributing Member

Originally Posted by

djandj

Great - you just let us know the website where we can order them then. Because Google knows nothing about it so far.

You could try these guys but not sure about shipping to US? GBP 39 for 5 in a carry case - M583 5 Rare WW2 ZB39 LMG Magazines - 08-Magazines & Loaders

-

-

03-08-2015 12:14 PM

# ADS

Friends and Sponsors

-

Contributing Member

Originally Posted by

djandj

A "few bucks"??? 54R is .22 per round SHIPPED. Today's price for .303 = .70 per not counting shipping. I'd say at nearly 4 times cheaper, it's still worth fiddling with 54r.

But if the ammo is sh*t and you're having nothing but trouble, doesn't that defeat the purpose ?

I don't know about you, but my range time is somewhat limited. I want my guns to work, and work properly. Everytime i've run into a 54R Bren, or something converted to run what it wasn't originally designed for, it seems to me like a problem in the making. But hey ho, your gun, your time, your call.

The greatest LMG to ever see service in the British Army...........................

-

The Following 2 Members Say Thank You to csmarcher For This Useful Post:

-

Legacy Member

Many others have successfully converted their Brens to 54r. I have a 1919a4 converted to 54r and it runs perfectly. The first barrel the builder used also split the cases, but it did not cause stoppages like this barrel does. It is clearly something to do with the barrel or headspacing etc.

---------- Post added at 07:32 AM ---------- Previous post was at 07:32 AM ----------

Originally Posted by

desperatedan

I just heard back from them. They WILL NOT ship ANYTHING to the US. I have no idea why. They did not elaborate.

-

-

I am more than convinced that it is an ammo batch problem Dan. Ignore me if I've said this before but what about trying some brass cased 762x54. I appreciate that steel is strong and tough (?) but there's steel - and there's steel. And you can be sure that the one-way-trip steel your cases are made of ain't gonna be good, believe me.

I appreciate that there's brass and there's brass too, but brass is very pliable and elastic. But the metallurgists here such as JM, Breaky and others that while the steel cases blow out and re-form slightly at the neck (in the recut chamber) it's supported while it does so. At the UN-supported extractor way, the steel blows. But not all steels......... some is as good as gold. You gotta find the batches that ain't going to blow

-

Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

Originally Posted by

desperatedan

Typically, from the ITAR/AECA regulations, import into the US requires prior approval via an approved ATF Form 6 Import Permit- this is not that hard to do as an individual, but requires a certain fondness for working you way through the ATF websites. You can download the required Form here:

http://www.atf.gov/files/forms/downl...-f-5330-3a.pdf

Notwithstanding the above, there is an extant exemption to the import regulations that permits INDIVIDUALS to import, on a "casual basis", things like this as long as the value does not exceed $100.00. That would appear to be the case here with these mags. The process is simple- as long they will ship it to you here in the US, just order them. If they get stopped in Customs, which is HIGHLY unlikely you will have to fill out a Declaration Form indicating value, personal use, etc.

-TomH

-

-

ON that basis, needy US owners might contact a UK forumer and come to some agreement. Such as having a few shipped to a UK address and just shipped onwards for the price of a jiffy bag! Small packet rate is fairly reasonable and just needs a stick-on CN22 declaration.

forumer and come to some agreement. Such as having a few shipped to a UK address and just shipped onwards for the price of a jiffy bag! Small packet rate is fairly reasonable and just needs a stick-on CN22 declaration.

-

-

Legacy Member

I am more than convinced that it is an ammo batch problem Dan. Ignore me if I've said this before but what about trying some brass cased 762x54. I appreciate that steel is strong and tough (?) but there's steel - and there's steel. And you can be sure that the one-way-trip steel your cases are made of ain't gonna be good, believe me.

I appreciate that there's brass and there's brass too, but brass is very pliable and elastic. But the metallurgists here such as JM, Breaky and others that while the steel cases blow out and re-form slightly at the neck (in the recut chamber) it's supported while it does so. At the UN-supported extractor way, the steel blows. But not all steels......... some is as good as gold. You gotta find the batches that ain't going to blow

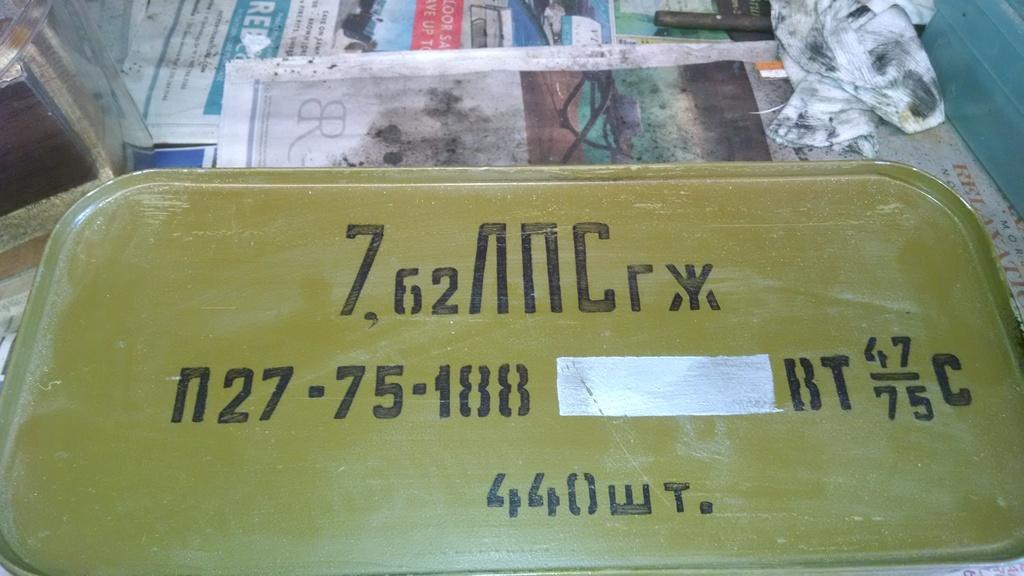

Peter - you may be right. As I mentioned I have over 100 rounds shoot perfectly well through that gun and barrel. However, the disturbing part is that spam cans are fungible. It's not like I can say "just don't by brand X ammo" etc. I was shooting regular old Russian 147 light ball. The rounds are indistinguishable from one another. The only thing I have on the can at this point is D64 on the bottom. That doesn't tell me much. But if Troy says the barrel is cut right and good to go, I will pop open the next spam can and pray. (and report back for all of you)

147 light ball. The rounds are indistinguishable from one another. The only thing I have on the can at this point is D64 on the bottom. That doesn't tell me much. But if Troy says the barrel is cut right and good to go, I will pop open the next spam can and pray. (and report back for all of you)

-

-

Legacy Member

-

Thank You to djandj For This Useful Post:

-

Legacy Member

Originally Posted by

djandj

so... does head spacing matter when the casing is unsupported on the sides no matter how close the rim of the case sits?

Djandj,

I know I can't give you any new advice. In one respect or another your problem is "head-spacing". You comment above indicates you don't understand the problem. Both TactAdv and I told you Troy wasn't going to solve your problem since you only sent him the barrel and consequently he couldn't check for a headspace problem.

IMO it's one of three problems:

1 - Head-spacing is too loose. It may work for .303 but I doubt the 7.62x54R is as tolerant as the British round. The 7.62 only has to move a very small amount for the pressure to see the thin wall od the case.

round. The 7.62 only has to move a very small amount for the pressure to see the thin wall od the case.

2- Timing is off so that the bolt is opening too early allowing too much pressure on the case as it extracts.

3-The bolt is hitting the two lugs on the receiver before it closes on the cartridge. Could happen but not as likely as the two above.

Here is some relevant reading material:

Login

Headspace 101 for .303s in The Lee Enfield Forum Forum

Login

The Bren can be checked for headspace with practically no tools or gages. More to follow.

Joe

Last edited by Joe H; 04-27-2015 at 06:04 PM.

-

-

Legacy Member

Djandj,

Here is a simple way to check headspace on a Bren. The rim thickness on the 7.62 is .063" so you can use the same headspace dimensions as the .303. The Bren was never designed for the 7.62x54r so I'd keep the headspace as low as possible.

Strip the frame, carrier and bolt. Remove the firing pin and extractor from the bolt. Take a properly resized MT case or unfired 7.62x54r case with the powder and bullet removed. The 7.62 x 54r is within .001" of the .303 british rim so you can check using the .303 headspace dimensions. Check the rim thickness. It should be about .063". It is a little difficult to check since the head is not flat. Glue on a .003- .004" piece of shim stock on the head of the case. Slide the case in the barrel. Now only install the bolt without extractor, no carrier spings etc, only the Bolt. Push it into the locked position. Push the bolt forward with your finger. The case should be snug under the bolt. If it isn't check Item 3 above. With your finger still pushing on the bolt and using a feeler gage you should have between .002" and .005" between the bolt and locking shoulder. If its .010" or better you may have problems. If its .015" plus IMO you definitely will have a problem. You probably will have to replace the locking shoulder with a longer one.

Every time the bolt closes the relationship of the carrier and bolt should be as in the attached pic. The carrier should have to travel 3/8" to 1/2" before the bolt unlocks. If you don't you may have problem 2 above.

The second pic shows the gap between the bolt and locking shoulder on a Bren that was having the same problems as you.

Joe

Last edited by Joe H; 04-27-2015 at 07:03 PM.

-

Thank You to Joe H For This Useful Post:

PM

PM