-

Legacy Member

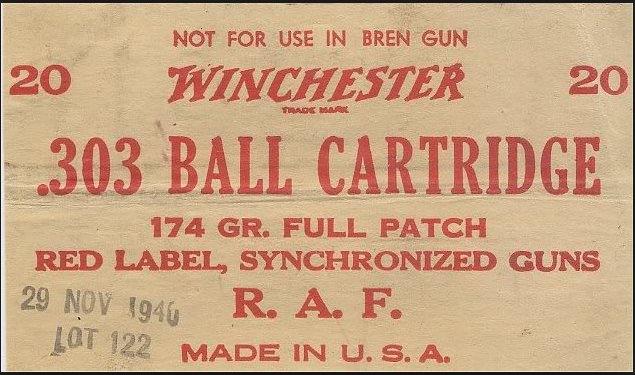

Here's the RAF ammo Roger mentioned. Does anyone know why it was not suitable for the Bren gun?

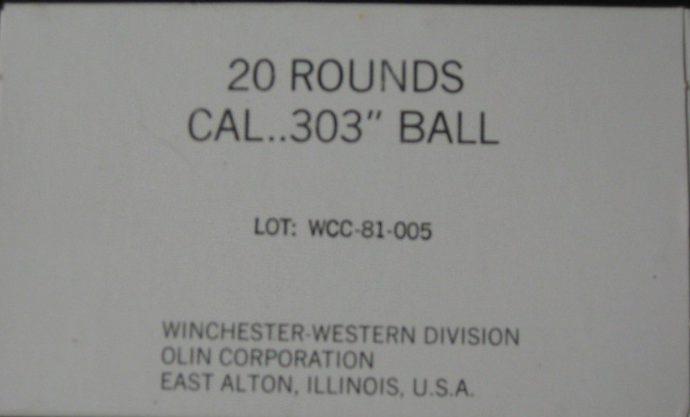

Winchester also loaded some in the early 80's. Wonder who it was for?

-

The Following 2 Members Say Thank You to no4mk1t For This Useful Post:

-

08-21-2018 05:27 PM

# ADS

Friends and Sponsors

-

Advisory Panel

It was rumored to be for Afghanistan at the time.

-

-

Advisory Panel

re "Not For Use In Bren" this ammo was weaker in head than standard and gave case separations.

-

-

I wouldn'tsay that the case was weaker. The bren has a distinct primary extraction phase during bolt unlocking whereas the Browning extraction is most ferocious. I'd say that the full patch was the reason.

-

-

Legacy Member

300 total in a sealed can for 50 -round bandoliers, 288 for 32- round cartons. 250 for a Vickers belt.

-

Thank You to Maxwell Smart For This Useful Post:

-

Legacy Member

I know the WW2 contract 303 from Winchester was loaded with ball powder but is it a non corrosive primer? Full patch is just another way of saying Full Metal Jacket back in the old days. Winchester would use that wording on just about all of it's FMJ ammo from just before WW1 up into WW2.

-

-

Legacy Member

The ONLY "service ammo" that was "non-corrosive" before about 1950, was .30 Carbine, and the only reason that happened was because of the "non-user-serviceable" gas piston setup. (Beware of the odd batches of Chinese Carbine ammo made in the last couple of decades; definitely corrosive. Come to think of it pretty much ALL "Eastern Bloc / Chinese" and "client" sourced ammo is corrosively primed, but it works fine and your guns won't rot away if you use it, unless you fail to perform correct cleaning practices.

If you are in a very dry place, like Northern Canada in mid winter, or the middle of the Atacama Desert, not a problem. If you live in places like Florida, coastal Queensland or similar, you will hear the rust forming overnight.

in mid winter, or the middle of the Atacama Desert, not a problem. If you live in places like Florida, coastal Queensland or similar, you will hear the rust forming overnight.

The stuff is NOT mercuric primed, thus it is reloadable brass. Better to sell it as "collector" ammo and buy nice new commercial brass and primers with your winnings.

Last edited by Bruce_in_Oz; 08-26-2018 at 10:51 PM.

-

-

Advisory Panel

I wouldn'tsay that the case was weaker. The bren has a distinct primary extraction phase during bolt unlocking whereas the Browning extraction is most ferocious. I'd say that the full patch was the reason.

Got the info about the weaker case and not use it in Bren from a WW2 vet who had a long career as a SA instructor in reg force. Otherwise he liked it as it was noncorrisive.

I have found this ammo separates after only few reloads in comparison with DI which lasts must longer which indicates a weak case.

Full patch Means full jacketed like other MkVII ctgs.

-

-

Hi Bruce. I'm interested in your comments in post #17 above. You mention that no 'service ammo' was non-corrosive before 1950 (I'm only interested in 303, so the exception of .30 carbine doesn't matter to me personally). Does this mean that the WW2 US contract ammo by Winchester WAS corrosive? If so, this means that we cannot equate a boxer (smaller) primer with what the primer is actually filled with. I had always assumed, perhaps erroneously, that, at least with WW2 contracts, the smaller boxer primer equated with being non-corrosive.

And to take it a step further; I spend a lot of time each year on the Somme where I regularly come across WW1 US contract 303 ammo. Again, even 1915 dated rounds by Peters & The US Cartridge Company (for example) bear the smaller boxer primer. Being of such vintage, would these definitely be corrosive?

TIA.

-

-

Legacy Member

Roger:

The Germans were among the first to go away from mercuric primers way back in the early 20th. Century. I recall that the Swiss and the Swedes were keen on the same thing. If the primer cups are "copper" it is almost certainly Mercuric primed, as the mercury does evil things to brass, as every potential and actual reloader of once-fired military .303 brass that originated in Britain

and the Swedes were keen on the same thing. If the primer cups are "copper" it is almost certainly Mercuric primed, as the mercury does evil things to brass, as every potential and actual reloader of once-fired military .303 brass that originated in Britain , Australia

, Australia , India, etc will attest.

, India, etc will attest.

All primers had the chlorate component to extend the "brissance" of the initial "flash" from the mercuric or lead-based "initiator". It is the "chlorate" reducing to "chloride" during that process that causes the problem.

Early "non-corrosive" priming brews were tried in many sporting cartridges, but military uptake was slow. This seemed to be partly because of the old, "if it ain't broke, don't fix it" mindset; in a military situation, the Sergeants would be supervising weapons cleaning and especially that carried out before returns to the armoury. Civilian users? Not quite the same degree of "adult supervision".

Secondly, early "con-corrosive" brews were found to be "unreliable" in extreme heat or cold and it took a fair while to do "aging" tests to see what happened in long-term storage, even under ideal conditions.

Somewhere around here I have a bit of data on the various service primer recipes: To the Bat-Cave! There is no way anyone should be contemplating "rolling their own" primer mixtures and "re-filling" primers unless their insurance is VERY comprehensive.

There were several attempts to introduce "non-corrosive" primers to various military systems, but until it could be ascertained that it was worth the effort, not much changed.

Universal fielding of gas-operated rifles and machine guns post WW2, saw rapid adoption of not just non-corrosive ammo, but the parallel rise in the extensive use of hard-chromimg of barrels, gas pistons and cylinders, and so on. The hard-chroming was not just to ward off corrosion, but to reduce wear and particularly, erosion in barrels. Stainless steels are useless in machine-gun barrels because they erode even faster than Moly steel at the high temperatures that develop, especially during "sustained" fire. The "Green Machine'" can be fairly profligate with replacement of "critical" parts like barrels when the need arises. Those of us without such lush, tax-payer-funded budgets need to be a little more circumspect and resist the urge to send next month's family food budget down-range whilst burning out an irreplaceable barrel.

And even when shooting within sane budgets, "cleanliness is next to ..... " and all that jazz.

-

The Following 2 Members Say Thank You to Bruce_in_Oz For This Useful Post:

PM

PM