Well, my last TRW bolt is now mated to a 2009 ployech shorty barelled receiver. What a big job this time! the Poly lugs were so tight, the TRW would not even rotate closed - not even close - with no gauge in the chamber at all!

So here we go, lapping at home on the cheap for dummies.

1) You need to put even back pressure on the bolt so that the lugs lap evenly. There are plenty of expensive jigs you can buy, or you can do like I do and cut a casing in half and chop a 1911 recoil spring in half to make a back force tool.

2) You need lapping compound. Brownells sells some fancy stuff, of for under $5, you can get valve grinding compound at Cambodian Tire.

3) You need GO and NOGO gauges. I use Clymer .308 SAAMI, but any will do so long as they are for the type of ammo you plan to use. I plan to shoot SAAMI match ammo, so...

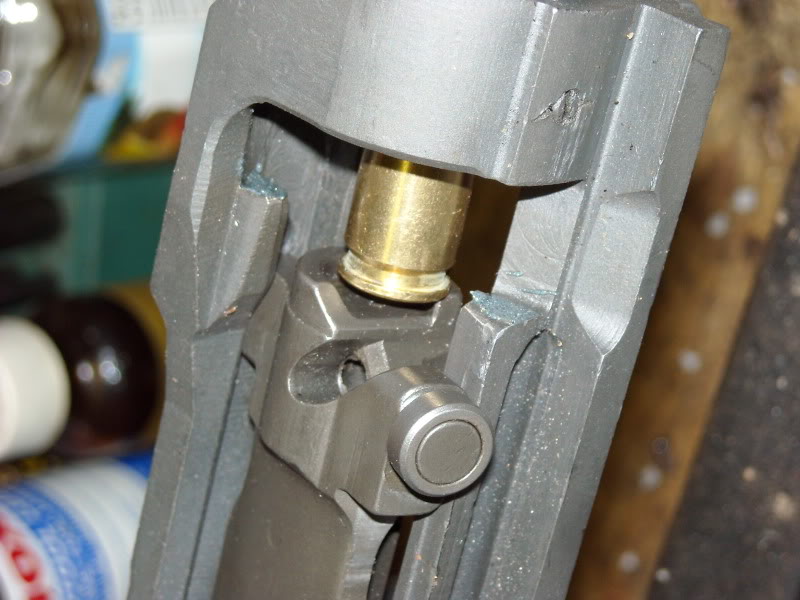

4) This is the setup you need to duplicate. Put compound ONLy on the lug faces. Nowhere else. Minimum every 100 laps or so, you need to clean everything off and check your headspace with the GO gauge. If you want a match chamber you stop lapping JUST as the bolt will close on a GO.

5) I use a punch through the extractor hole to rotate the lugs up and down on the lug seats - only about 10 degrees of rotation back and forth.

6) In this photo you can see it's getting close. You want to stop when the bottom of this lug flat rests on the op rod guide ledge with the GO gauge in the chamber.

7) This is what the seats look like as they are lapped.

8) Done! Lapped and right at minimum SAAMI.

Now one final issue I had is that this bolt, for some reason would not fully open. I traced it to the rear left lug being too thick on the bottom. Odd because on my other USGI bolts, this was not an issue and they dropped right into this receiver, but this TRW bolt had to have a few thou skimmed off the bottom of that lug so that it would not bind in this receiver. It *JUST* fit in my other receivers, so I imagine it's an issue of this one receiver being slightly too narrowly inletted at the heel. Of well, it works great now.

The bright area is where I had to grind off about 5 thou to make the receiver and bolt work so that the bolt would fully open without binding:

And there you have it...Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM